A2-11 Spindle Nose Drawing

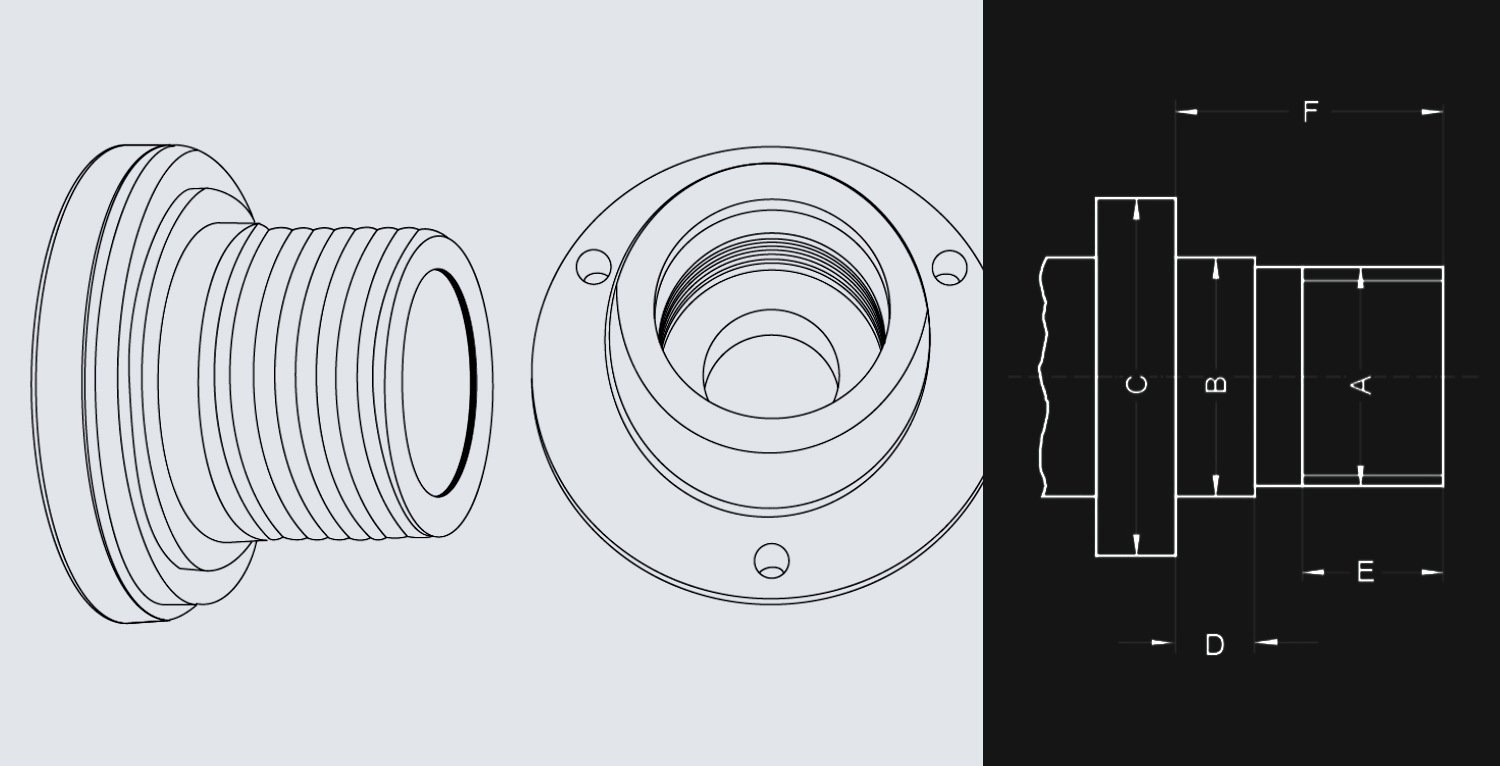

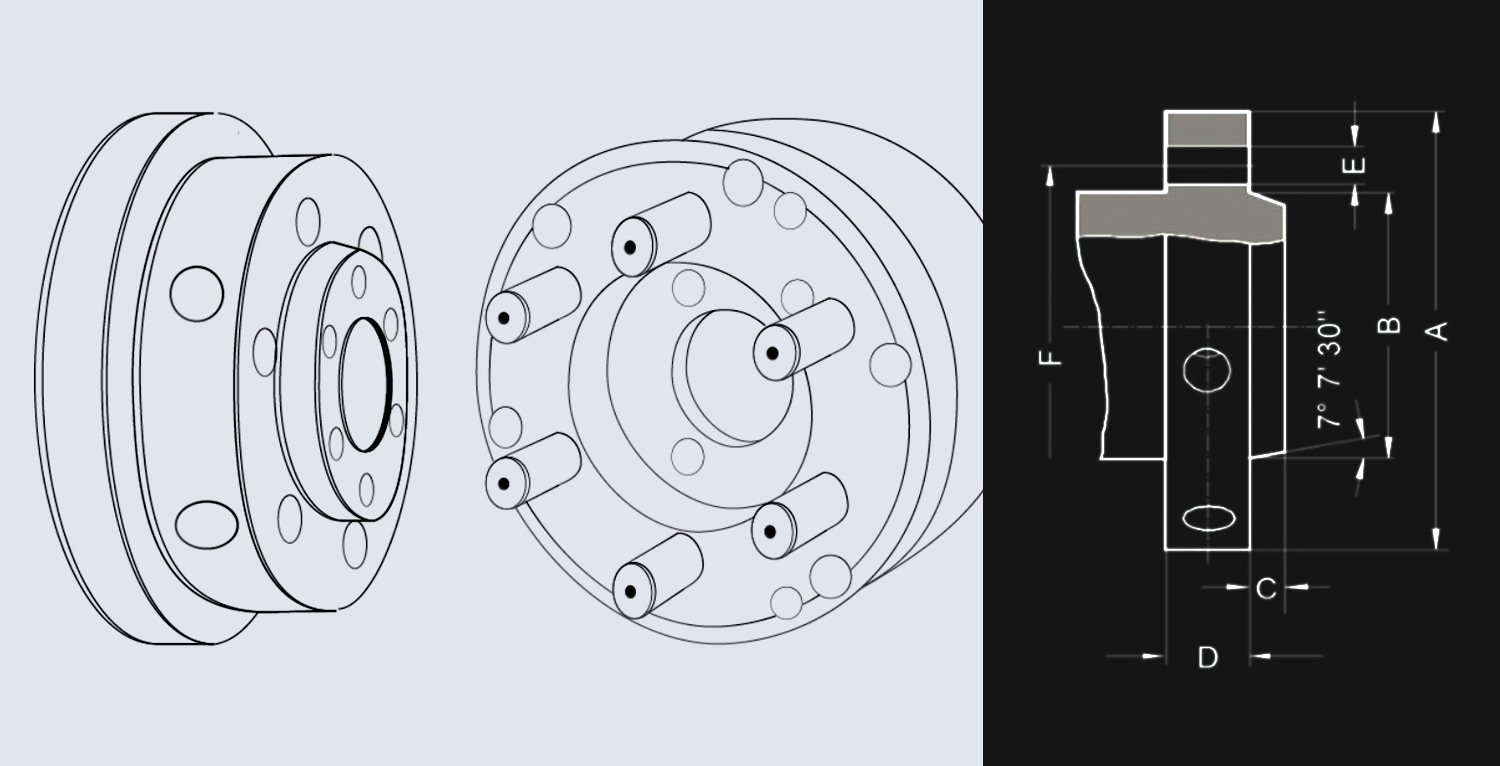

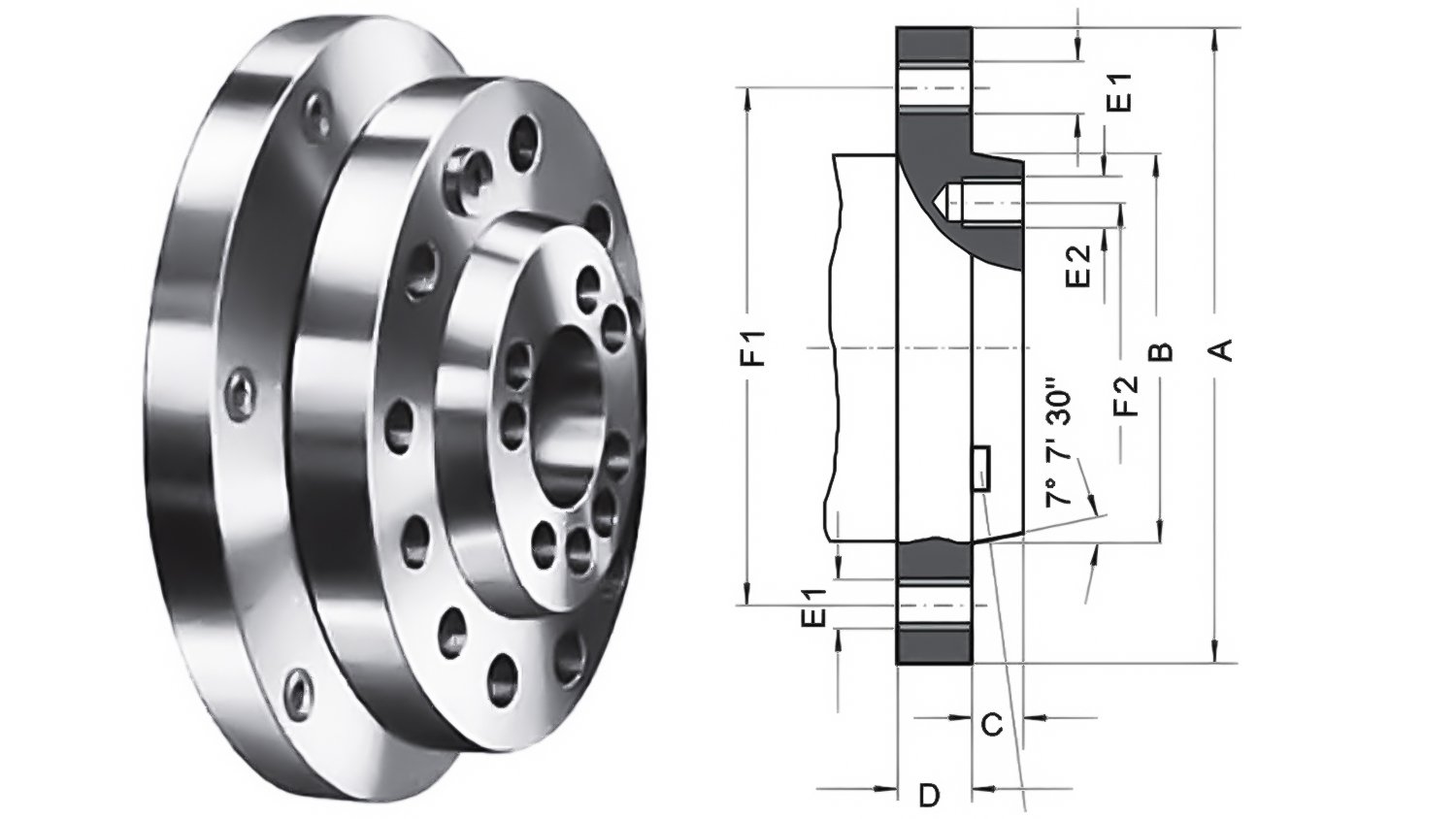

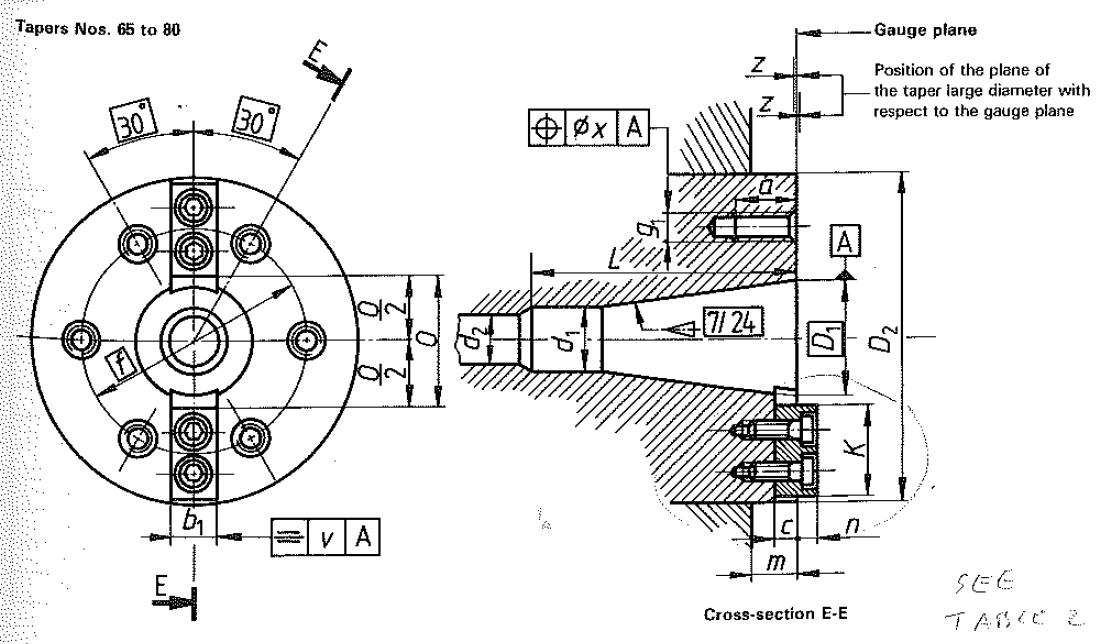

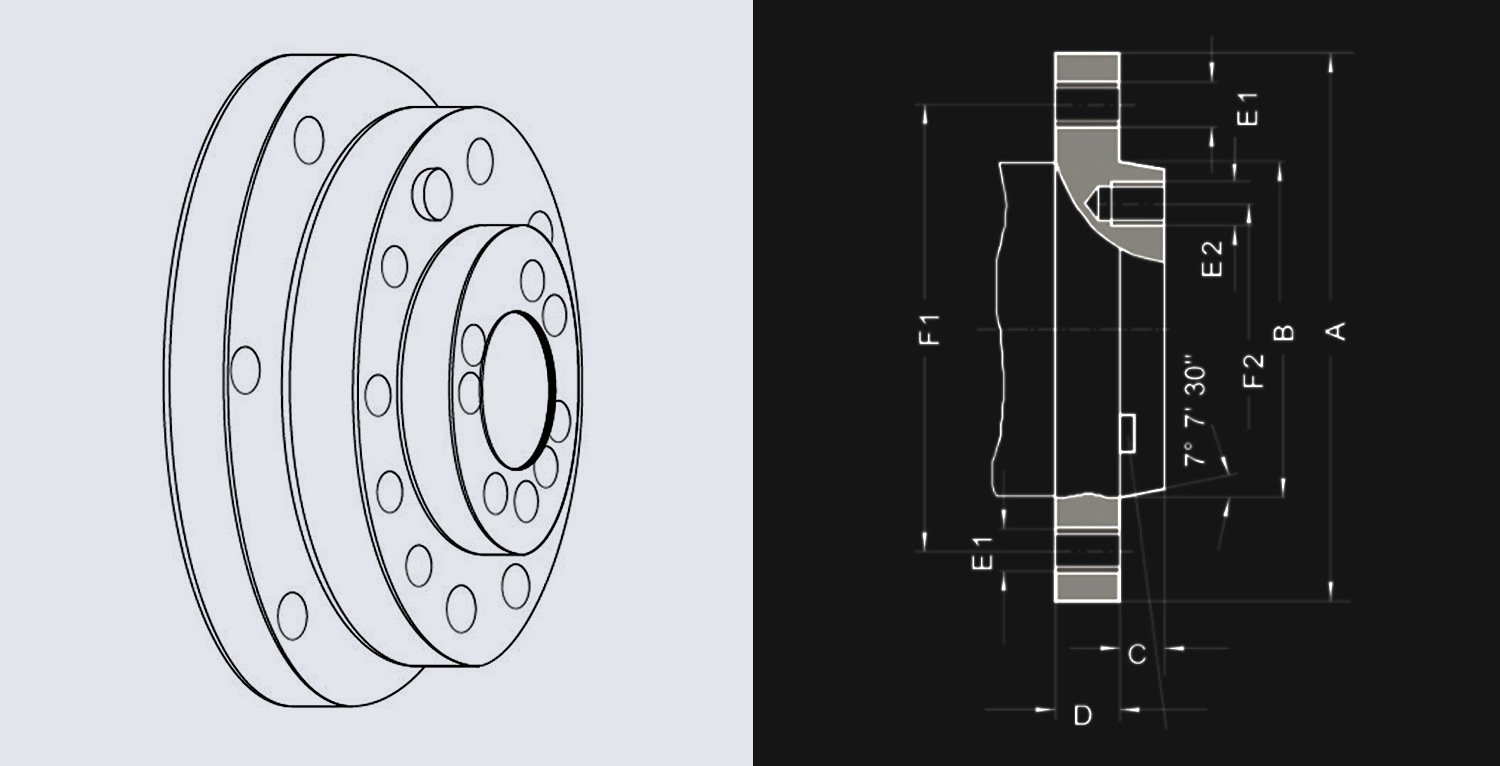

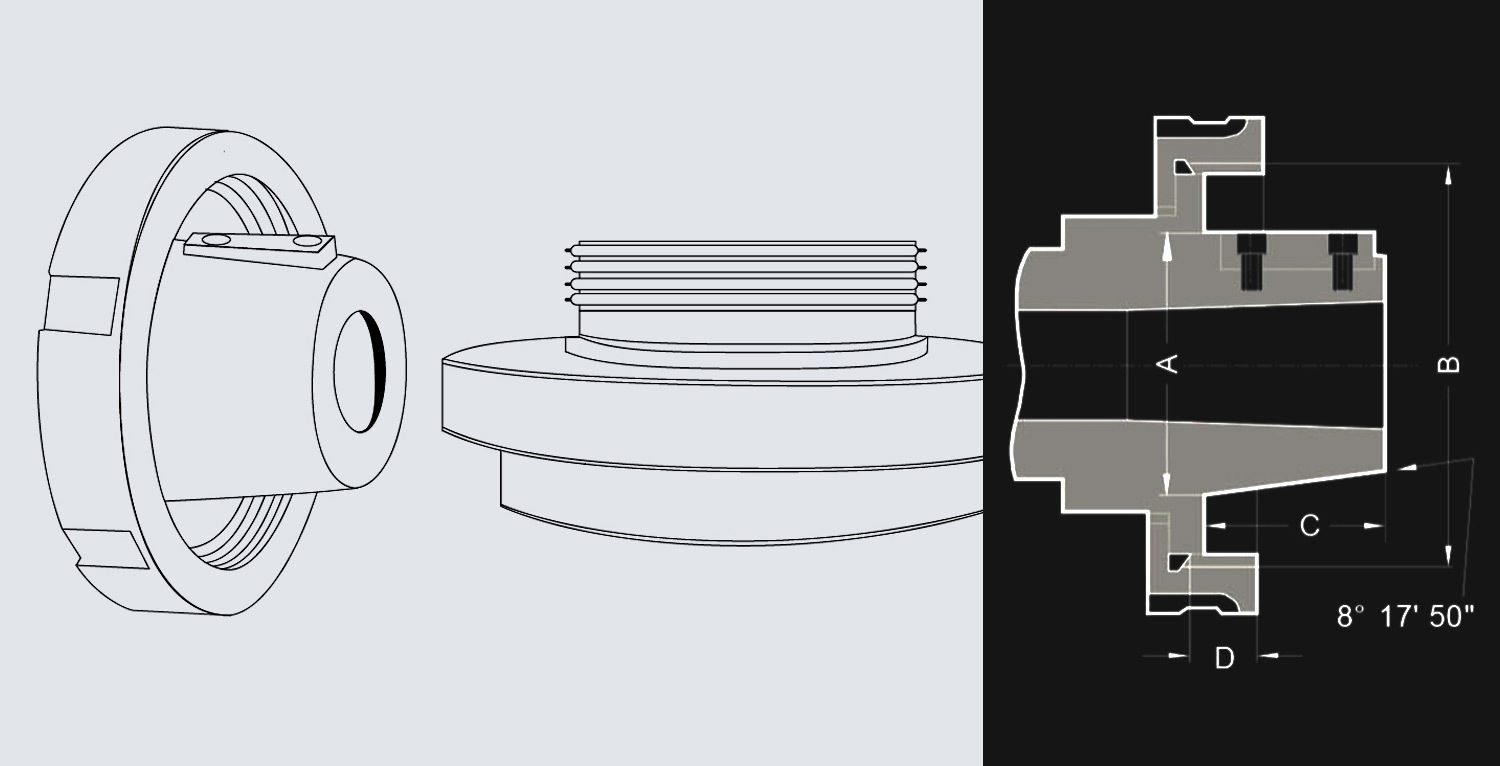

A2-11 Spindle Nose Drawing - Thread m175 x p3.0 1.96” long. Web determining an a type spindle and size. Web 3114 technical data machine spindle noses for din and asa b 5.9 machine spindle noses are not included in the scope of delivery! Tapped holes in fl ange (outer bolt circle) and in inner bolt. (current production) drawtube stroke =.99. Web the second thing is the number, a1 or a2. The machine does not include a chuck or hydraulic union standard; Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Web the spindle nose has taper for centring and locating fittings, a key for positive drive and a flanged retention nut. Tapped holes in fl ange (outer bolt circle). Tapped holes in fl ange (outer bolt circle) without inner bolt circle. 6.50 id (7.08 id) 6.50 id. (current production) drawtube stroke =.99. Web the second thing is the number, a1 or a2. The machine does not include a chuck or hydraulic union standard; Web practical application m/c spindle nose plate bptl adaptor plate customer component fixture bptl advantage run out of locating taper to front end diameter for fixture. This is the bolt pattern on the nose of the spindle used to mount the chuck, not the bore through the spindle. Tapped holes in fl ange (outer bolt circle) and in inner bolt.. Tapped holes in fl ange (outer bolt circle). Thread m175 x p3.0 1.96” long. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. The machine does not include a chuck or hydraulic union standard; Web practical application m/c spindle nose plate bptl adaptor plate customer component fixture bptl advantage run out of locating taper to front end. Thread m175 x p3.0 1.96” long. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Tapped holes in fl ange (outer bolt circle) and in inner bolt. Tapped holes in fl ange (outer bolt circle). Web practical application m/c spindle nose plate bptl adaptor plate customer component fixture bptl advantage run out of locating taper to front. Tapped holes in fl ange (outer bolt circle). 6.50 id (7.08 id) 6.50 id. Thread m175 x p3.0 1.96” long. The machine does not include a chuck or hydraulic union standard; Web the second thing is the number, a1 or a2. Tapped holes in fl ange (outer bolt circle). Tapped holes in fl ange (outer bolt circle) without inner bolt circle. This is the bolt pattern on the nose of the spindle used to mount the chuck, not the bore through the spindle. Web the spindle nose has taper for centring and locating fittings, a key for positive drive and a. The machine does not include a chuck or hydraulic union standard; Measure the pilot diameter and length (b & c) measure the bolt circle diameter (f1 and f2) and diameter of the holes. Tapped holes in fl ange (outer bolt circle) and in inner bolt. (current production) drawtube stroke =.99. Web practical application m/c spindle nose plate bptl adaptor plate. Web 3114 technical data machine spindle noses for din and asa b 5.9 machine spindle noses are not included in the scope of delivery! Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Web the second thing is the number, a1 or a2. Web machine spindle noses to ansi b 5.9; (current production) drawtube stroke =.99. Web the second thing is the number, a1 or a2. Tapped holes in fl ange (outer bolt circle) and in inner bolt. The machine does not include a chuck or hydraulic union standard; Web 3114 technical data machine spindle noses for din and asa b 5.9 machine spindle noses are not included in the scope of delivery! 6.50 id (7.08. Tapped holes in fl ange (outer bolt circle) and in inner bolt. Web the spindle nose has taper for centring and locating fittings, a key for positive drive and a flanged retention nut. (current production) drawtube stroke =.99. Measure the pilot diameter and length (b & c) measure the bolt circle diameter (f1 and f2) and diameter of the holes.. The machine does not include a chuck or hydraulic union standard; Web machine spindle noses to ansi b 5.9; Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Thread m175 x p3.0 1.96” long. Web the spindle nose has taper for centring and locating fittings, a key for positive drive and a flanged retention nut. Web practical application m/c spindle nose plate bptl adaptor plate customer component fixture bptl advantage run out of locating taper to front end diameter for fixture. Tapped holes in fl ange (outer bolt circle) and in inner bolt. 6.50 id (7.08 id) 6.50 id. Web determining an a type spindle and size. Tapped holes in fl ange (outer bolt circle). (current production) drawtube stroke =.99. Web 3114 technical data machine spindle noses for din and asa b 5.9 machine spindle noses are not included in the scope of delivery!

Lathe Spindle Nose Standards & Lathe Chuck Mounting Types

IrfanView HTMLThumbnails

Lathe Spindle Nose Standards & Lathe Chuck Mounting Types

Lathe Spindle Nose Identification Chart

Spindle Nose Taper

![Spindle Nose [PDF Document]](https://cdn.vdocuments.net/img/1200x630/reader024/reader/2021030113/553feab74a7959c30f8b4897/r-1.jpg?t=1628903670)

Spindle Nose [PDF Document]

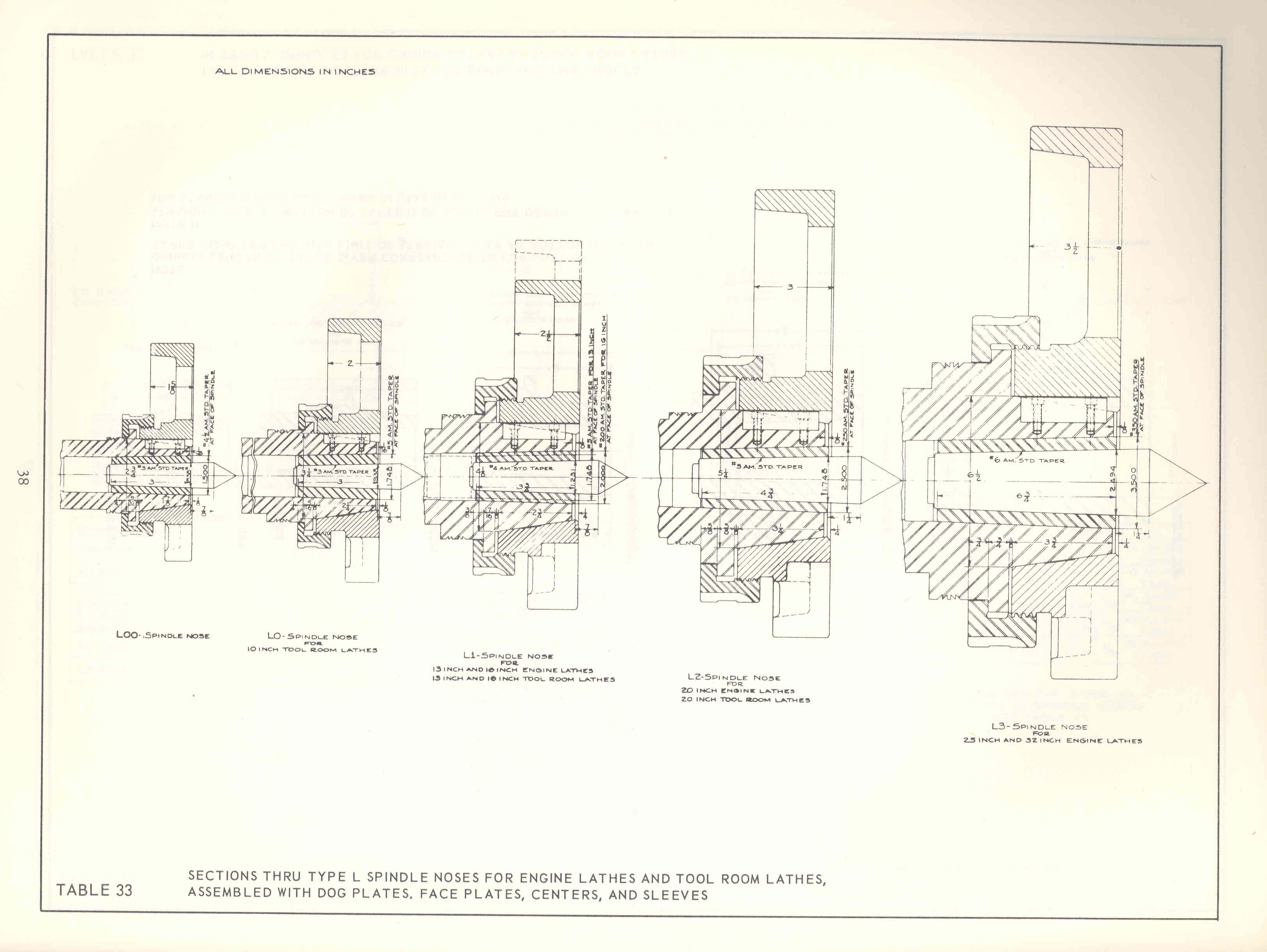

L Series Spindle Information

Lathe Spindle Nose Standards & Lathe Chuck Mounting Types

Repost Old spindlenose standard?`

Lathe Spindle Nose Standards & Lathe Chuck Mounting Types

Web The Second Thing Is The Number, A1 Or A2.

Measure The Pilot Diameter And Length (B & C) Measure The Bolt Circle Diameter (F1 And F2) And Diameter Of The Holes.

This Is The Bolt Pattern On The Nose Of The Spindle Used To Mount The Chuck, Not The Bore Through The Spindle.

Tapped Holes In Fl Ange (Outer Bolt Circle) Without Inner Bolt Circle.

Related Post: