Deep Draw Sheet Metal

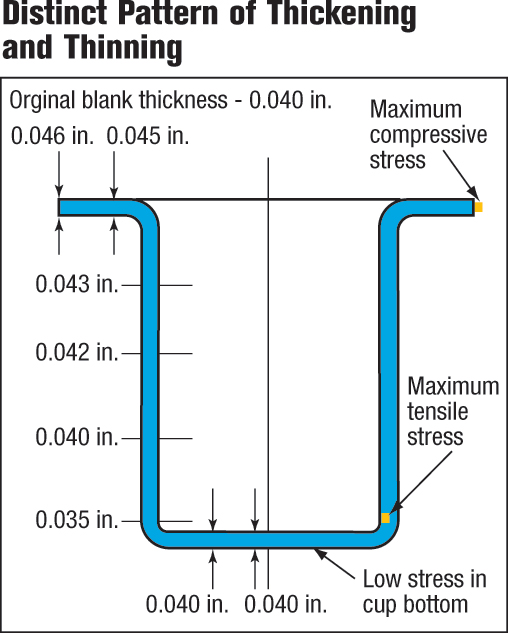

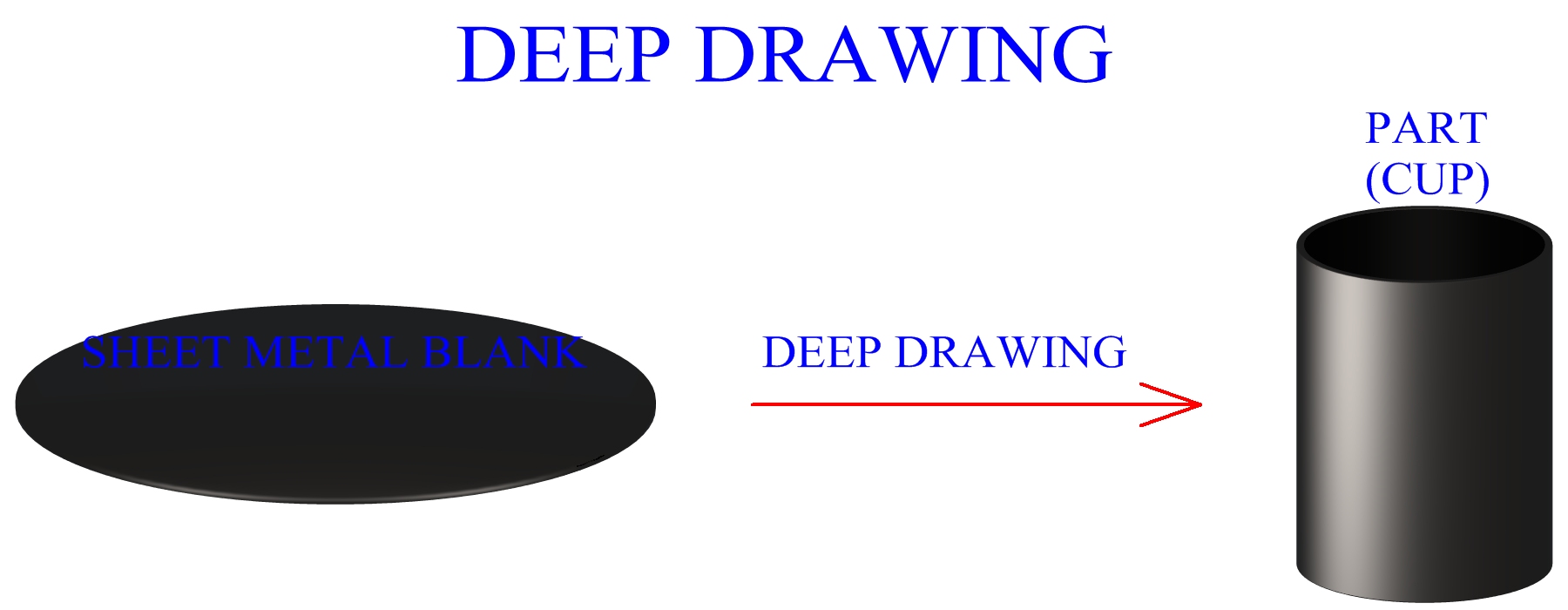

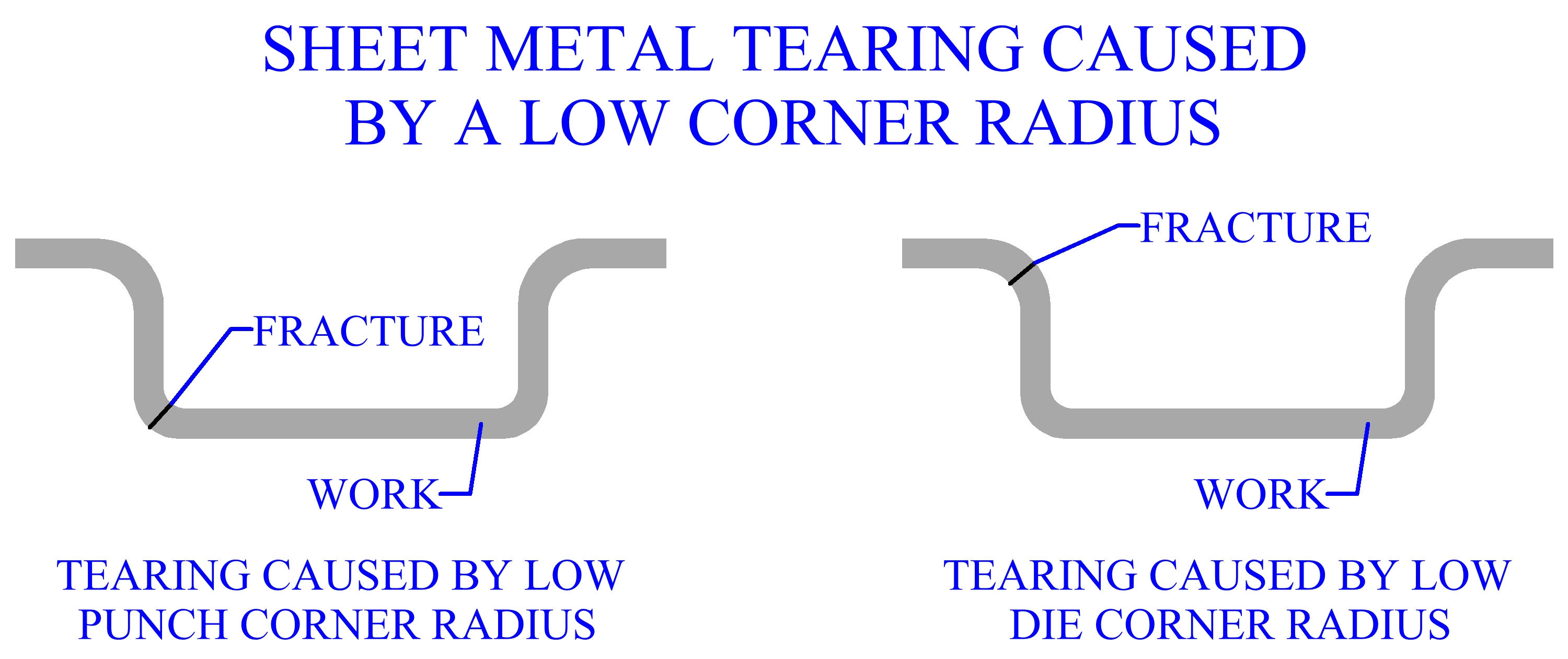

Deep Draw Sheet Metal - [1] it is thus a shape transformation process with material retention. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing. The press is then activated to force the punch against the die with up to 400 tons of force. The depth of the drawn parts often exceeds their diameter. Web the deep draw sheet metal process is used to create a wide range of products, from simple cylindrical shapes to more complex geometries. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Common applications include automotive parts, aerospace components, beverage cans, and household appliances. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Can deep drawing be used for all metals? Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling. Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling. Successful deep drawing depends on many factors. Common applications include automotive parts, aerospace components, beverage cans, and household appliances. The sheet metal, or metal blank, is placed on the die and secured. Deep drawn parts achieve their shape by drawing. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. The depth of the drawn parts often exceeds their diameter. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn. The press is then activated to force the punch against the die with up to 400 tons of force. It finds application in various industries but is best known for its use in the automotive industry. The sheet metal, or metal blank, is placed on the die and secured. Web deep drawing is a sheet metal forming process in which. What is deep drawing in sheet metal fabrication? Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling. Successful deep drawing depends on many factors. The process is repeated until the component achieves the desired size and shape. Web deep drawing is a metal forming process for creating seamless, sheet. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Successful deep drawing depends on many factors. [1] it is thus a shape transformation process with material retention. Common applications include automotive parts, aerospace components, beverage cans, and household appliances. Pots. Common applications include automotive parts, aerospace components, beverage cans, and household appliances. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its. Successful deep drawing depends on many factors. Web may 30, 2001 article bending and forming figure 1: Can deep drawing be used for all metals? Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. The process is considered deep drawing when. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. It finds application in various industries but is best known for its use in the automotive industry. Importance of accurate sheet metal drawings Successful deep drawing depends on many factors. The process is considered deep drawing when. The process is repeated until the component achieves the desired size and shape. It finds application in various industries but is best known for its use in the automotive industry. What is deep drawing in sheet metal fabrication? [1] it is thus a shape transformation process with material retention. Web deep drawing is a manufacturing process that is used extensively. Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. Web. Web the deep draw sheet metal process is used to create a wide range of products, from simple cylindrical shapes to more complex geometries. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing. Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. The process is repeated until the component achieves the desired size and shape. Successful deep drawing depends on many factors. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Web may 30, 2001 article bending and forming figure 1: It finds application in various industries but is best known for its use in the automotive industry. The sheet metal, or metal blank, is placed on the die and secured. Common applications include automotive parts, aerospace components, beverage cans, and household appliances. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. The depth of the drawn parts often exceeds their diameter. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling.

Deep Drawing Of Sheet Metal

Deep Drawing of Sheet Metal Stoeckli Metall AG Metalworking Center

Deep Drawing from A to Z MetalForming Magazine Article

Deep drawing of sheet metal

Deep Drawing Of Sheet Metal

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Metal forming deep drawing of sheet metal

Deep Drawn &Metal Stampings RAO Deep Draw & Metal Stamping Sheet

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

The Press Is Then Activated To Force The Punch Against The Die With Up To 400 Tons Of Force.

Can Deep Drawing Be Used For All Metals?

Importance Of Accurate Sheet Metal Drawings

What Is Deep Drawing In Sheet Metal Fabrication?

Related Post: