Deep Drawing Manufacturing Process

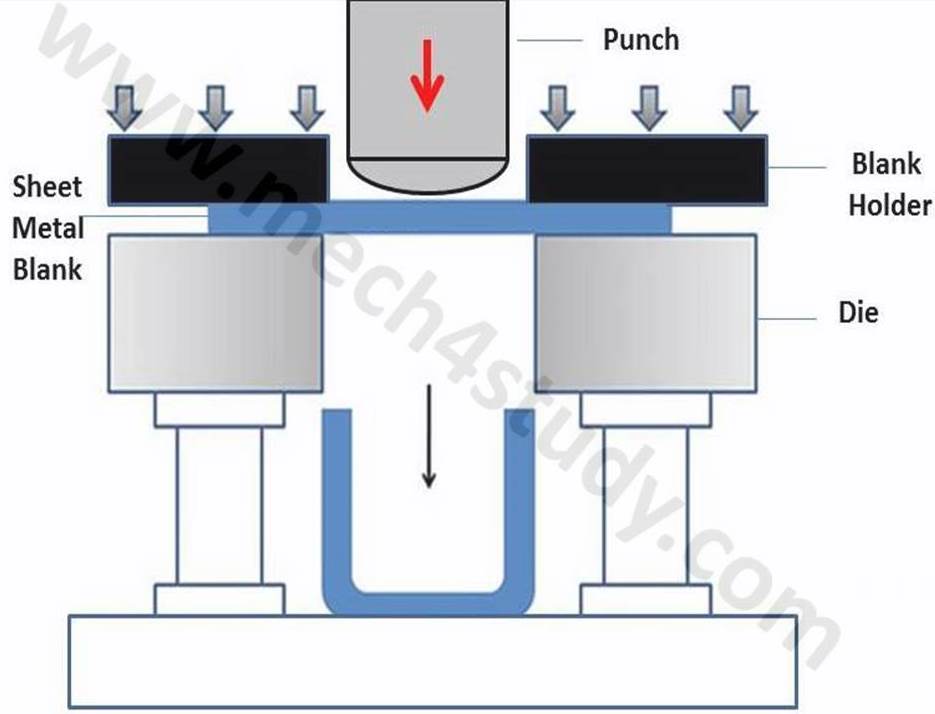

Deep Drawing Manufacturing Process - Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following: Deep drawing can be used. The sheet metal is placed between two dies, and the punch is forced against it to create the desired profile. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Deep drawing produces a part from a flat blank via the action of a punch force onto the blank. The blank is placed between the die and the holder and then deformed by the punch pushing the sheet into the die and the blank finally assumes the shape of the die. Deep drawing can be used for products that need less assembly and other manufacturing processes. Web deep drawing manufacturing, the competitive edge. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. Web application of deep drawing i. Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Web deep drawing manufacturing, the competitive edge. Web deep drawing (dd) is one of the sheet metal forming processes widely used in automobile, aerospace, electronics and allied industries to produce the hollow parts. Web deep drawing is. 2] it is combination of metal forming process & sheet metal process. [1] it is thus a shape transformation process with material retention. Web what is deep drawn manufacturing? Blankholder restraining force controls radial material flow into the die cavity. Very complex parts can be achieved using deep drawing. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. It assists in creating items such as pots and pans for cooking, containers, and automobile parts like panels and gas tanks. Deep drawing is used to make cups, bowls, and other hollow shapes from sheet metal. Web deep drawing manufacturing, the competitive. H dp ≥ 0.5 h d p ≥ 0.5 Web application of deep drawing i. Deep drawing can be used to produce large quantities in the shortest time, it is the most efficient method because. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Deep drawing can be used for products that need. Deep drawing, or simply drawing, is a widely known manufacturing process and is used extensively in the forming of sheet metal. Web deep drawing is a sheet metal forming process that uses a punch and dies to draw (pull) the workpiece into the desired shape. The process is considered deep drawing when the depth of the drawn part exceeds its. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. In the case of an. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following:. The improvement in the deep. The blank is placed between the die and the holder and then deformed by the punch pushing the sheet into the die and the blank finally assumes the shape of the die. Web deep drawing is a common process in industry for manufacturing products from sheet metals. 3] if the ratio of height to diameter. That force pulls (draws) the blank into a die cavity, causing the flange to compress circumferentially. Many cylindrical parts like metal can, pots, container for food and beverages, kitchen sinks, automobile fuel tank etc. Large quantities of products are easily manufactured through deep drawing complex. Web deep drawing is a sheet metal forming process that uses a punch and dies. Web deep drawing explained: Deep drawing produces a part from a flat blank via the action of a punch force onto the blank. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. The process is widely used for producing different products such as automotive parts,. Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. In the case of an. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Large quantities of products are easily manufactured through deep. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Deep drawing produces a part from a flat blank via the action of a punch force onto the blank. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing can be used to produce large quantities in the shortest time, it is the most efficient method because. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Large quantities of products are easily manufactured through deep drawing complex. That force pulls (draws) the blank into a die cavity, causing the flange to compress circumferentially. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Web deep drawing is a sheet metal forming process that uses a punch and dies to draw (pull) the workpiece into the desired shape. Web deep drawing is a manufacturing process that involves the use of a punch and die to form a sheet metal into a desired shape. The deep drawing process saves you time and money through the efficient use of material and the. The improvement in the deep. Web deep drawing is a common process in industry for manufacturing products from sheet metals. The process is widely used for producing different products such as automotive parts, cans, sinks and housing, and the application areas are getting larger every day. Very complex parts can be achieved using deep drawing. It assists in creating items such as pots and pans for cooking, containers, and automobile parts like panels and gas tanks.

Deepdrawn manufacturing process for MDI cans YouTube

The Deep Draw Hydroforming Process & Advantages American Hydroformers

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Manufacturing Processes Archives Page 2 of 4 ElectricalWorkbook

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

Deep Draw Process for Precision Metal Components TransMatic TransMatic

Deep Drawn Methodology and Its Benefits

What is Deep Drawing Process? Mech4study

Deep drawing of sheet metal

What is Deep Drawing Process? Mech4study

Web Deep Drawing May Be A Viable Production Solution For Any Manufacturing Process That Requires One Or More Of The Following:

Web Application Of Deep Drawing I.

The Blank Is Placed Between The Die And The Holder And Then Deformed By The Punch Pushing The Sheet Into The Die And The Blank Finally Assumes The Shape Of The Die.

Web Deep Drawing Explained:

Related Post: