Drawing Metal Sheet

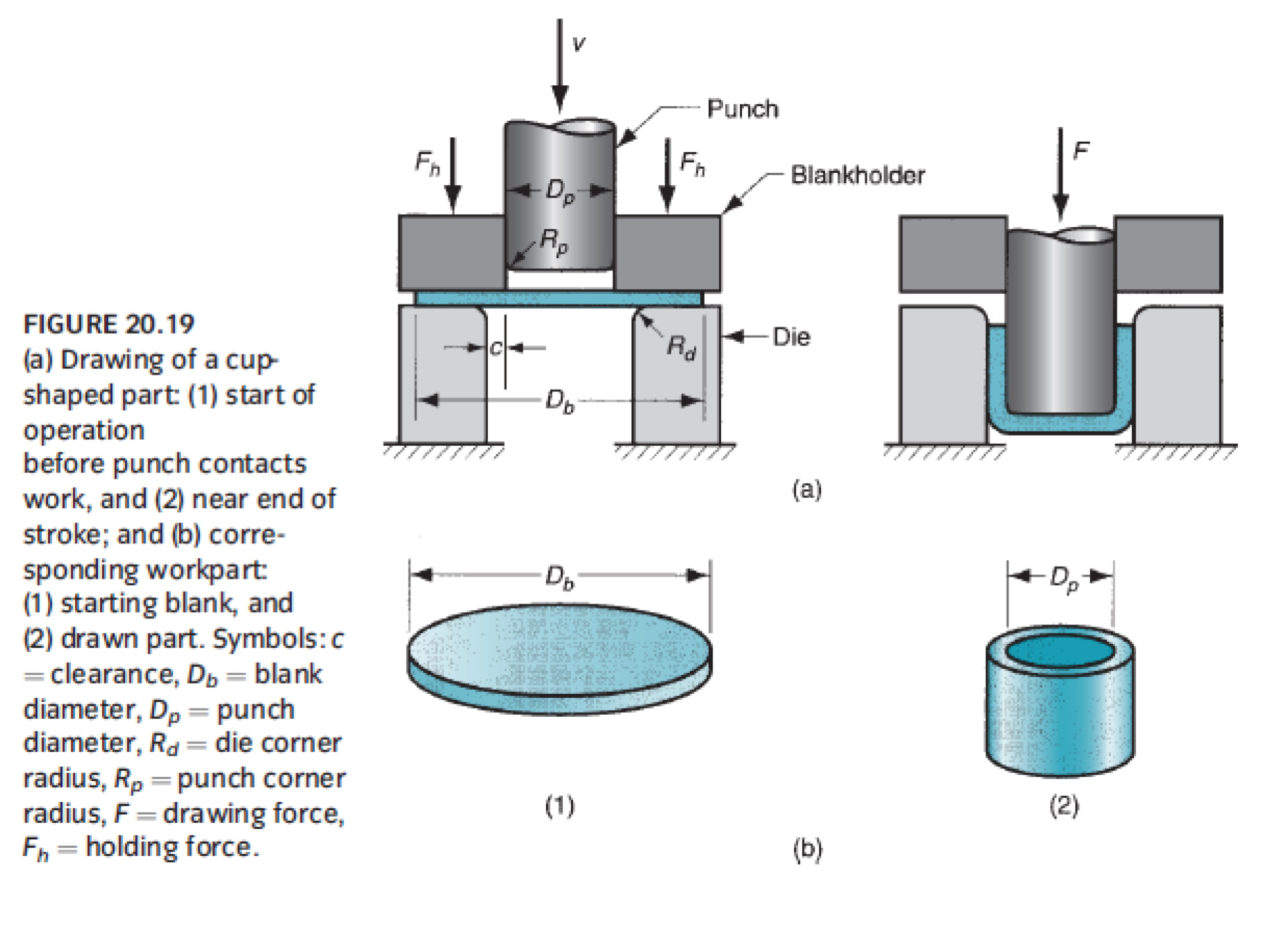

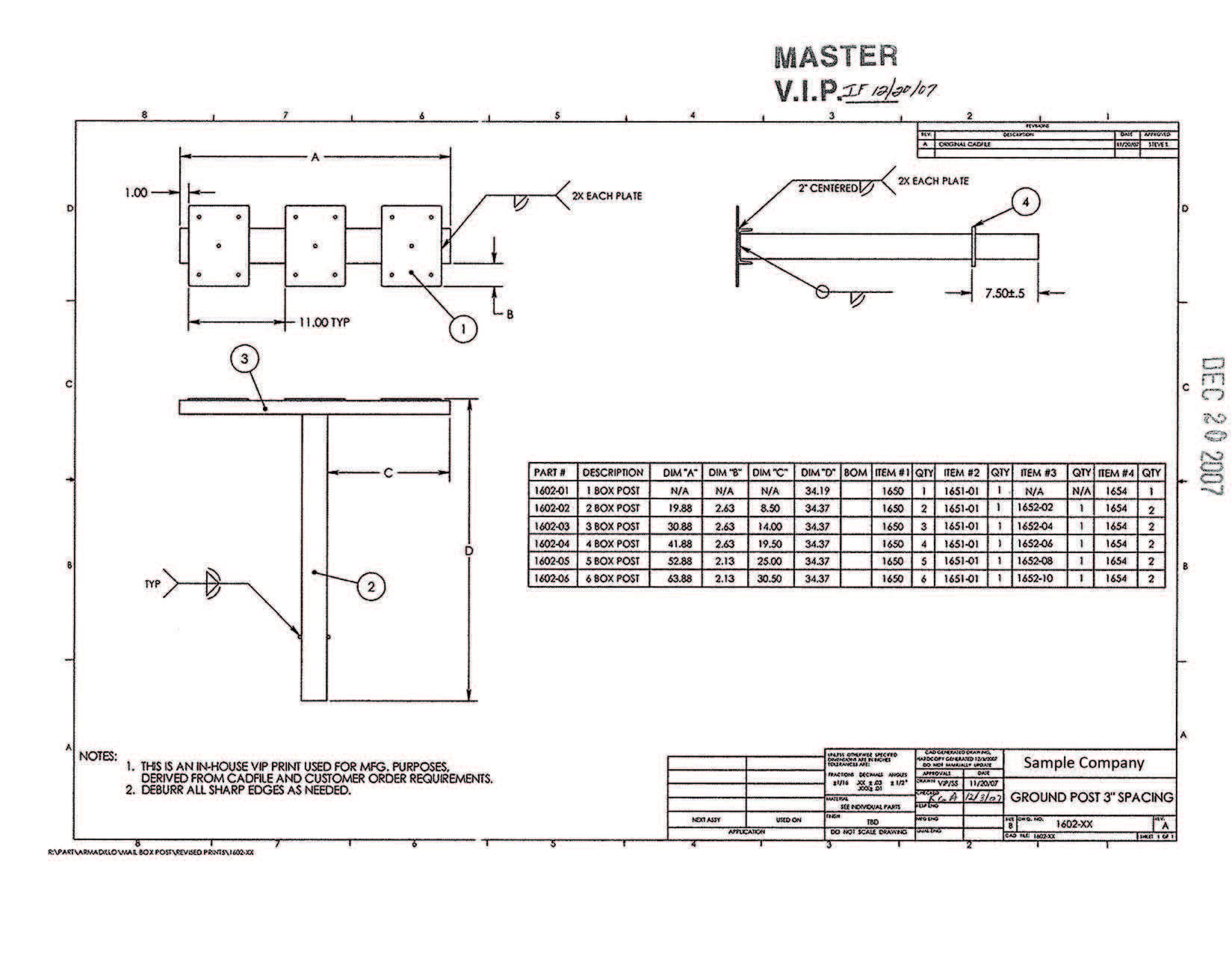

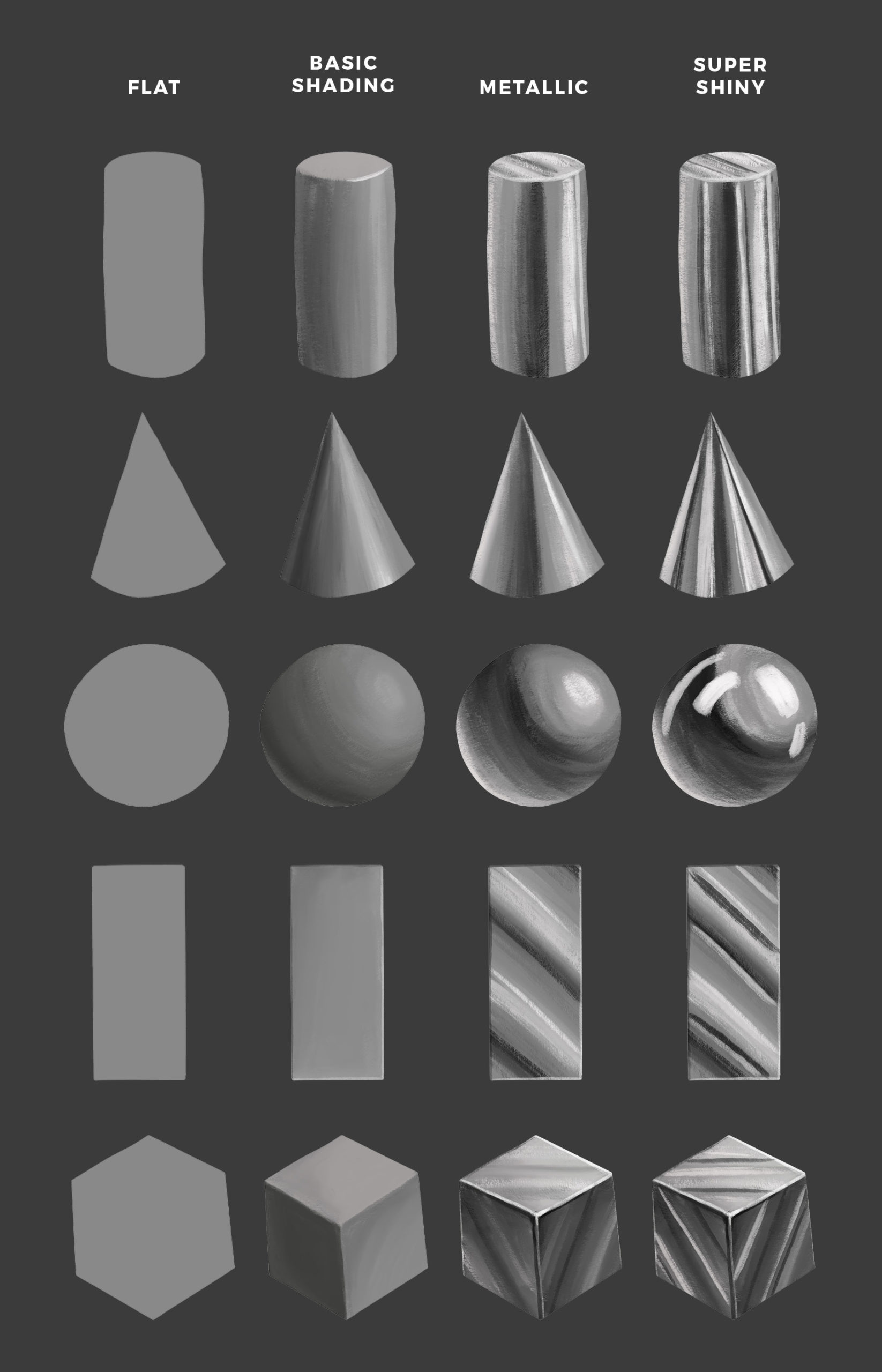

Drawing Metal Sheet - This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Panels can be mounted horizontally or vertically, depending on the look you want. Web coil and flat sheet metal fabrication: Practice a lot on cheaper metal sheets until you perfect your skills. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than the work. This is a general guideline, and the actual suitable thickness will change depending on the type of metal used, the manufacturer's capabilities, and the complexity of the metal part to be fabricated. This process is very similar to metal extrusion, the difference being in the application of force. —sheet metal drafting is merely the application of the principles of ordinary mechanical drawing to objects which, for the purposes of drawing, lack thickness. Sheet metal drawing is defined as a plastic deformation over a curved axis. Web this chapter explains how to create sheet metal drawings. Use the exact hardware name when possible; Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. Web a fully dimensioned drawing including dimensions for formed bends, countersinks, holes, flanges. Web sheet metal drafting. —sheet metal drafting is merely the application of the principles of ordinary mechanical drawing to objects which, for the purposes. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web industrial metal supply stocks the galvanized steel plate and sheet you need. This is a general guideline, and the actual suitable thickness will change depending on the type of metal used,. Start with simple designs and easy hand tools. List part numbers, not just the part name; The term sheet metal refers to any metal material formed into flat pieces, a process commonly known as sheet metal design. Web the beginner secret of cutting intricate details in sheet metal accurately and effortlessly is in the preparation. Web the art of drawing. Web forming basics laser cutting tolerances features sheet metal introduction these basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. This is accomplished by. Sheet metal drawing is defined as a plastic deformation over a curved axis. Web 1 5 ways to optimize drawings for precision sheet metal fabrication services. Web sheet metal forming is suitable for metal thicknesses of 0.6 mm to 6.35 mm. Submit your drawings using our request a quote form. Jeffrey lowe will share with you how to use colored. Web 1 5 ways to optimize drawings for precision sheet metal fabrication services. Web metzfab industries has extensive knowledge to manufacture sheet metal consoles and provide custom consoles to automobile, off road vehicles, gaming, lighting, aerospace, electronics, and security industries. Submit your drawings using our request a quote form. What is a 2d drawing? Make clean and fine line drawings. Use the exact hardware name when possible; Web a fully dimensioned drawing including dimensions for formed bends, countersinks, holes, flanges. Sheet metal drawing generally involves the manipulation or deformation of plastic over a curved axis. This is a general guideline, and the actual suitable thickness will change depending on the type of metal used, the manufacturer's capabilities, and the complexity. Sheet metal drawing generally involves the manipulation or deformation of plastic over a curved axis. Panels can be mounted horizontally or vertically, depending on the look you want. The fencetrac metal frame fence system accomodates corrugated panels up to 1″ deep. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. This article endeavors. Sheet metal drawing is defined as a plastic deformation over a curved axis. Web metzfab industries has extensive knowledge to manufacture sheet metal consoles and provide custom consoles to automobile, off road vehicles, gaming, lighting, aerospace, electronics, and security industries. It is a best practice to dimension to virtual intersection points and. This process is very similar to metal extrusion,. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than the work. Make clean and fine line drawings. A title block with your company name, part number, part description, scale, tolerances, units, etc. Web 1 5 ways to optimize drawings for precision sheet metal fabrication services. Web industrial metal supply stocks the galvanized. Web sheet metal drafting. By this is meant that the materials dealt with are usually in the form fig 1.—pictorial representation of anvil. Web you can also use other ribbed panels available from various manufacturers. Panels can be mounted horizontally or vertically, depending on the look you want. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than the work. Web coil and flat sheet metal fabrication: Web the beginner secret of cutting intricate details in sheet metal accurately and effortlessly is in the preparation. Jeffrey lowe will share with you how to use colored pencils to achieve a me. This process is very similar to metal extrusion, the difference being in the application of force. Sheet metal (also known as deep drawing) and wire, bar and tube drawing. What is a 2d drawing? This is a general guideline, and the actual suitable thickness will change depending on the type of metal used, the manufacturer's capabilities, and the complexity of the metal part to be fabricated. Web there are two main types of drawing: Sheet metal drawing is defined as a plastic deformation over a curved axis. Web a fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc…). Start with simple designs and easy hand tools.

sheet metal drawings for practice pdf Alyse Britton

Sheet Metal Shakotis

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

Metal Drawings at Explore collection of Metal Drawings

Autocad Sheet Metal Tutorial

Solidworks Tutorial Sheet metal drawings YouTube

Sheet Metal Practice Drawing

sheet metal drawings for practice pdf lineartdrawingsaestheticbutterfly

Autodesk Inventor Sheet metal Drawing Tutorial Basics YouTube

how to draw metal texture with pencil howtotieascarfaroundyourneckmen

Include Grain Direction As Needed;

Sheet Metal Drawing And Wire, Bar, And Tube Drawing.

Web The Art Of Drawing Metal Sheets Has Enabled Revolutionary Advancements In Design Paradigms And Provided Pathways For Improved Functional Capabilities.

Web Deep Drawing Is A Manufacturing Process That Is Used Extensively In The Forming Of Sheet Metal Into Cup Or Box Like Structures.

Related Post: