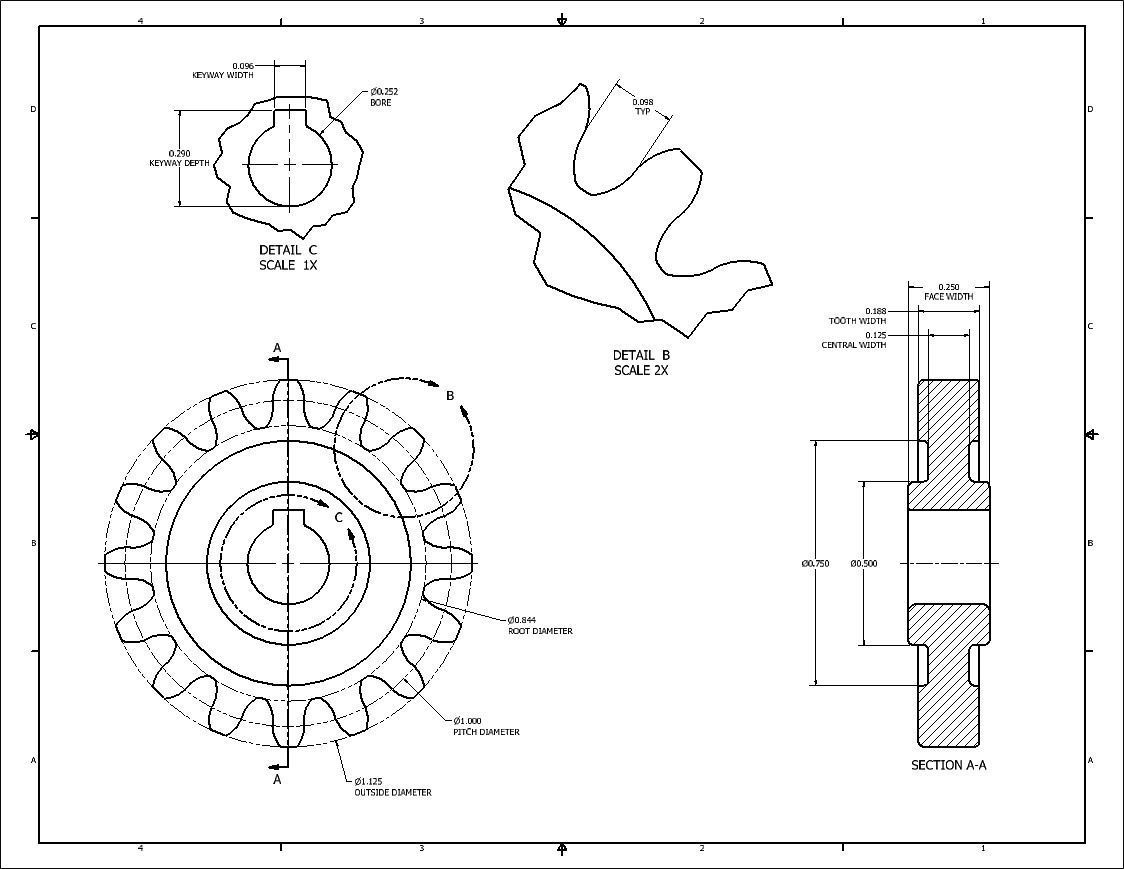

Drawing Of Spur Gear

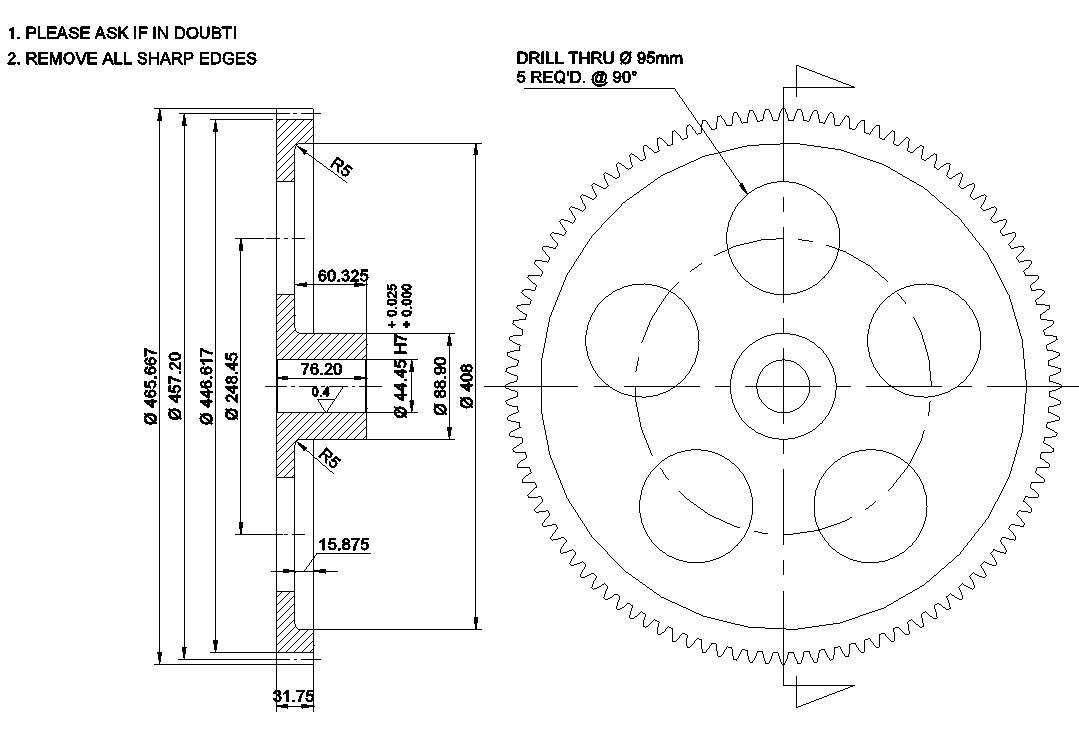

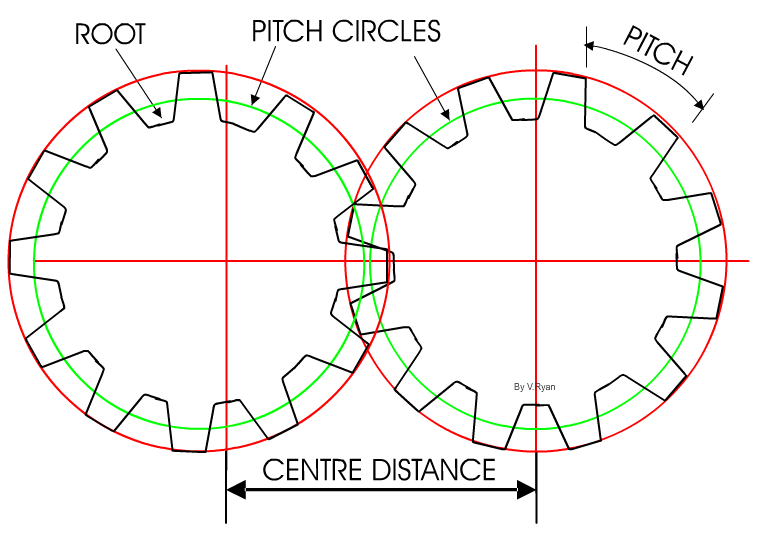

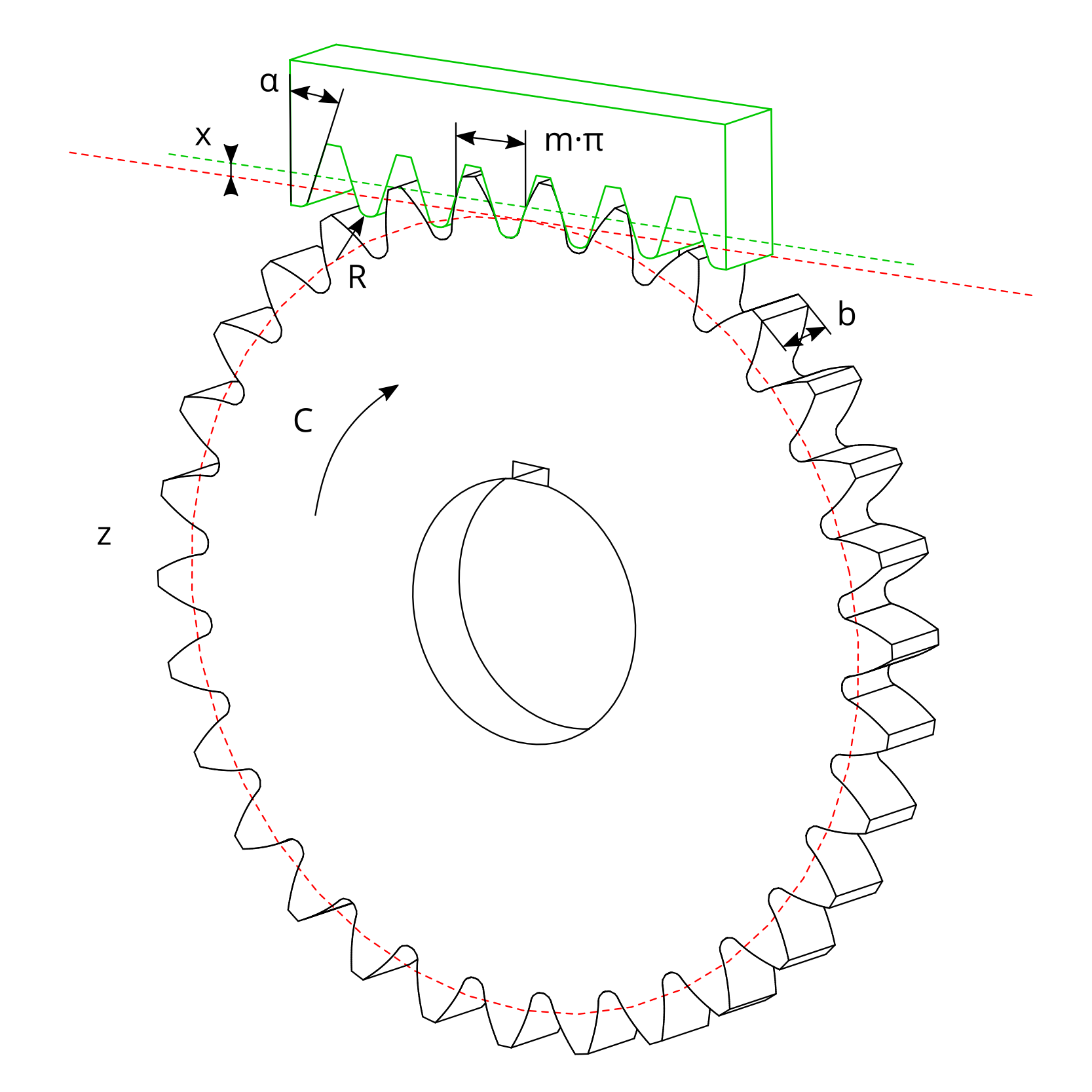

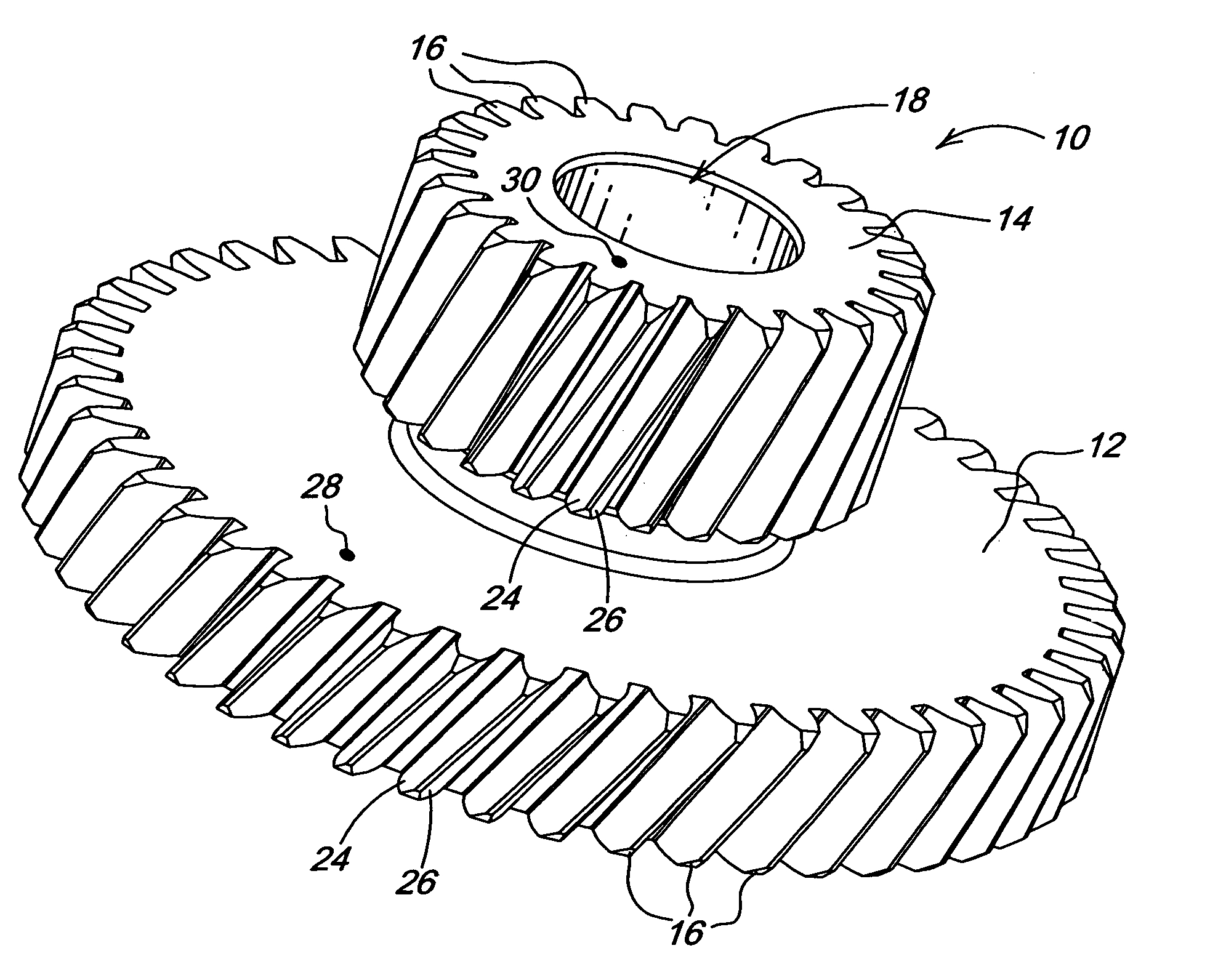

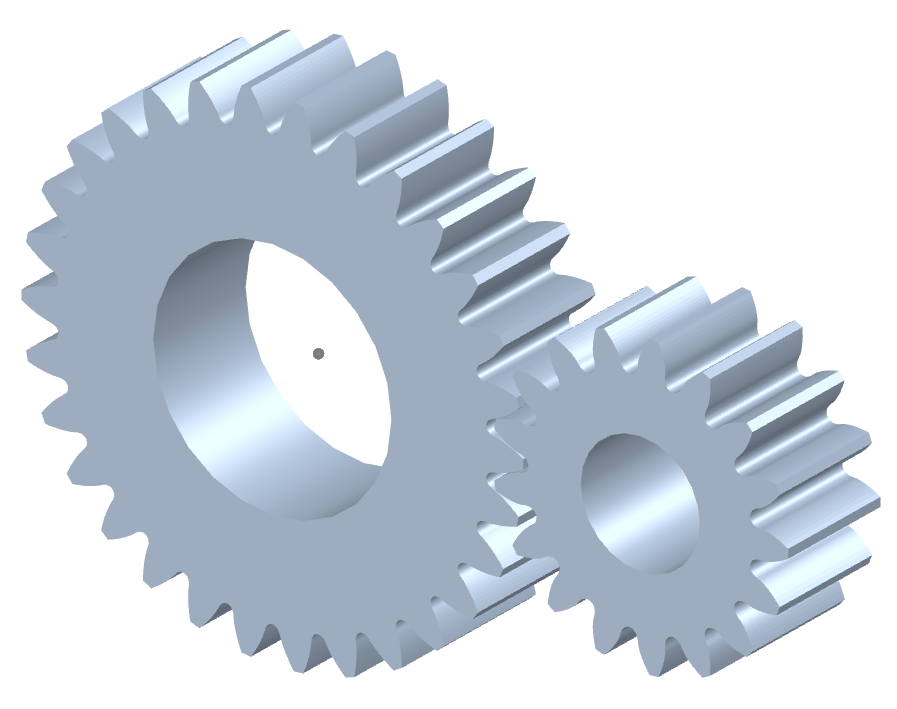

Drawing Of Spur Gear - Bigger, faster, noisier gears increase pressure. • if teeth are too large, the gear designer must: P n d = 1.5. Let’s see the processes to examine the shape of the gears from these basic. Web points c and d (where the addendum circles meet the pressure line) should be between a and b. Web 1.2k views 2 years ago. Very weak teeth increase number of teeth. Smaller teeth are weaker increase pitch circle radius. Various types of gears such as spur gears, bevel gears, rack gears, worms, and internal gears can be drawn, and the drawings can be. Web drawing an involute spur gear (hd) this video details the process of drawing an involute spur gear by hand in solidworks. This process includes determining the number of teeth, the module (which is the ratio of pitch diameter to the number of teeth), the pitch circle, and the tooth shape, among other things. Web the design of spur gear is simple. To design successful spur gear systems, we must adopt an engineering approach. Web this free, highly functional gear drawing software. Web make the profile of the gear tooth spaces. Rsdelivers.com has been visited by 10k+ users in the past month First, you need to configure your design environment and choose the spur gear from the library. Trim the circles side ways. Web this free, highly functional gear drawing software allows you to easily create gear drawings by entering various parameters,. Calculate and draw the pitch circle. Web in this vedio focused on draw base circle by given pressure angle and by using mini drafter. Web 1.2k views 2 years ago. Web in this tutorial video i will sketch spur gear in solidworks with the help of toolbox.please subscribe our channel for more videos and projects in solidworks. • if teeth. To design successful spur gear systems, we must adopt an engineering approach. Bigger, faster, noisier gears increase pressure. But let's try something new. In this comprehensive guide, we will walk you through the process. It will show the boundary creation dialogue. Web 1.2k views 2 years ago. Web spur gear systems are one of the most used engineering systems in the machine elements world. Very weak teeth increase number of teeth. Web drawing a spur gear in millimeters involves a series of technical steps which require precision and an understanding of gear mechanics. Choosing the right spur gears. Web make the profile of the gear tooth spaces. Web this free, highly functional gear drawing software allows you to easily create gear drawings by entering various parameters, hub shapes, hole dimensions, keyway dimensions, and other information. • if teeth are too large, the gear designer must: Follow along using the transcript. Rsdelivers.com has been visited by 10k+ users in. We can also use pedit command. Choosing the right spur gears. Trim the circles side ways. When the spur gears are engaged the contact will be to the entire width parallel to the axis of the shaft due to this there will sudden application of load. Let’s see the processes to examine the shape of the gears from these basic. Draw lines from the center of the circle to these points to function as the teeth’s base. The diameter of the pitch circle is calculated below; Five key features of our spur gears. This tutorial gives a different approach on drawing a spur gear. Web spur gear systems are one of the most used engineering systems in the machine elements. Web this calculator generates the.dxf and.svg files for making external spur gears, rack and pinion sets, and internal spur gears. Follow along using the transcript. Even in the case of a gear that does not have spur teeth or that has an odd number of teeth. Web engineering drawings for spur and helical gears $ 220.00 the thors course, engineering. First, you need to configure your design environment and choose the spur gear from the library. Even in the case of a gear that does not have spur teeth or that has an odd number of teeth. Common applications of spur gears. What is a spur gear? Web a comprehensive guide to drawing and understanding spur gears how to draw. Web the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to control speed, power, and torque. Drawing a spur gear manually might seem like a daunting task,. Let’s see the processes to examine the shape of the gears from these basic. What is a spur gear? Click inside the region and then press. Web the design of spur gear is simple. Web drawing a spur gear in millimeters involves a series of technical steps which require precision and an understanding of gear mechanics. The diameter of the pitch circle is calculated below; Various types of gears such as spur gears, bevel gears, rack gears, worms, and internal gears can be drawn, and the drawings can be. Very weak teeth increase number of teeth. This process includes determining the number of teeth, the module (which is the ratio of pitch diameter to the number of teeth), the pitch circle, and the tooth shape, among other things. A spur gear calculator uses parameters including the tooth count, gear module, and pressure angle to generate the key dimensions of an external spur gear. Even in the case of a gear that does not have spur teeth or that has an odd number of teeth. We can also use pedit command. Web 1.2k views 2 years ago. Trim the circles side ways.

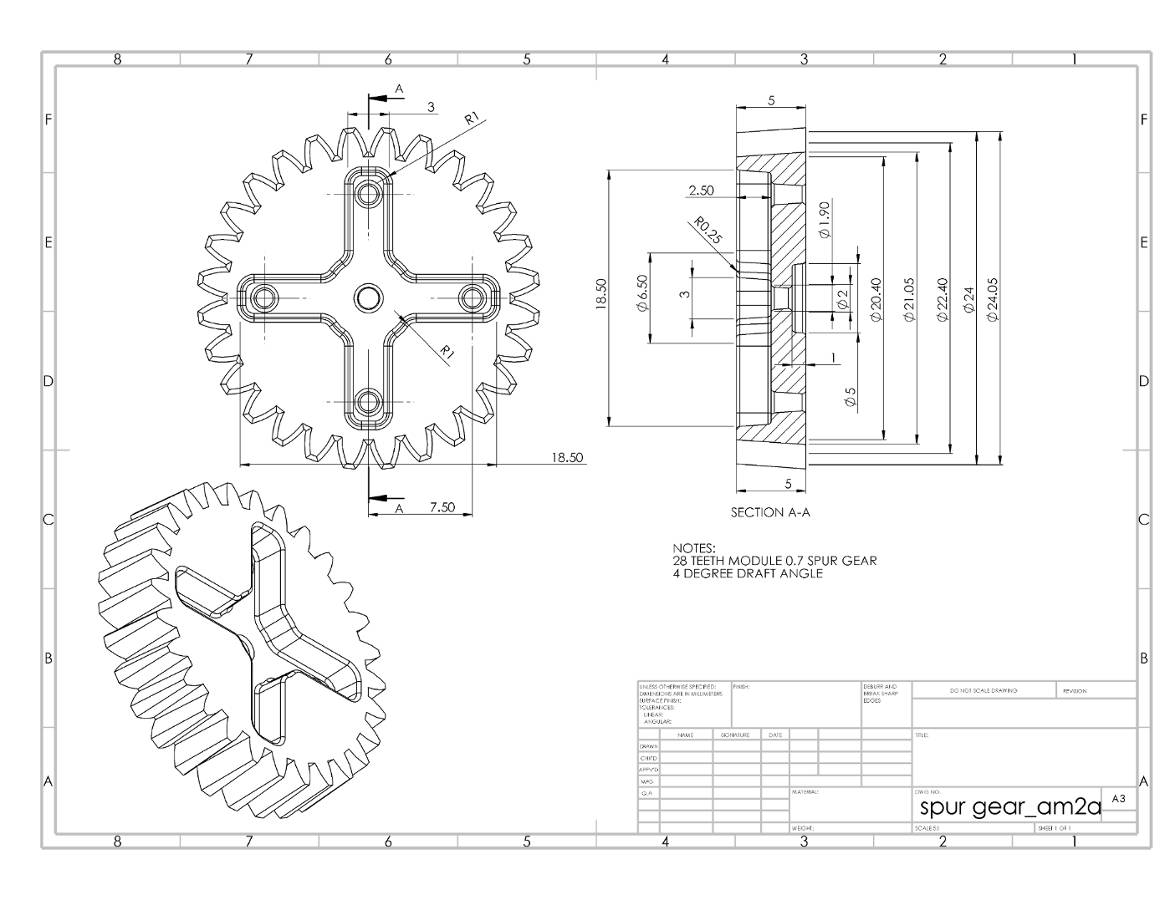

spur gear drawing autocad download howdoesdigitalartwork

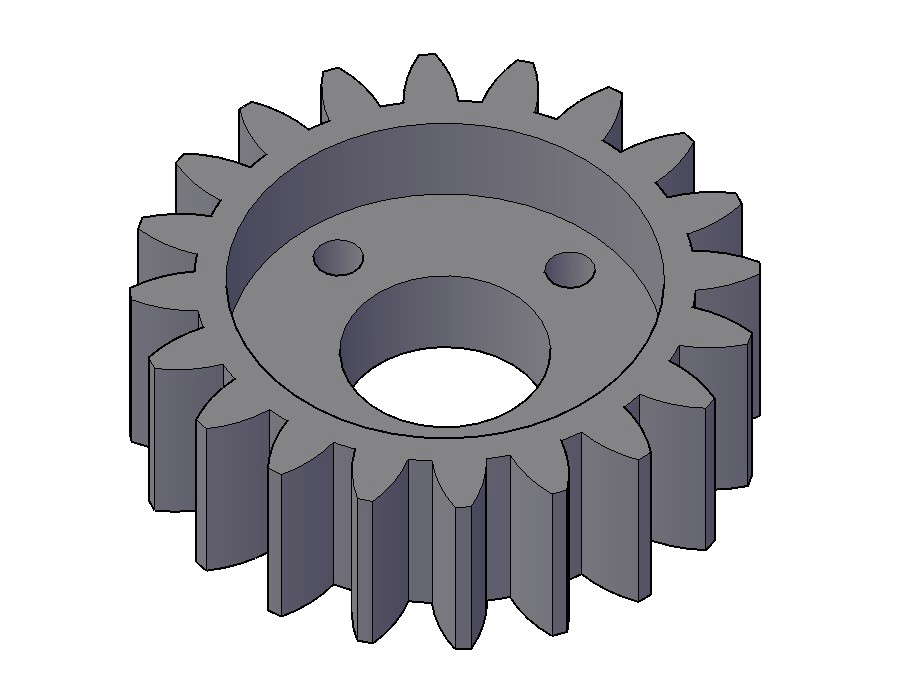

Isometric view of the Spur Gear 20T M2.25 Section and Elevation

Spur Gear Drawing at Explore collection of Spur

Spur Gear Drawing at GetDrawings Free download

Spur Gear Sketch at Explore collection of Spur

Spur Gear Drawing at GetDrawings Free download

Spur Gear Drawing at GetDrawings Free download

Spur Gears Geometry of spur gears and gear meshes

Spur Gear Drawing at GetDrawings Free download

Spur Gear Drawing at GetDrawings Free download

With The Use Of Equations It Creates A Robust Design That Solves For All Possible Configurations You Can.

Using This Example You Will Be Able To Draw A Spur Gear Having Any Number Of Teeth And Pitch.

2.2 Pitch Surface Draw The Pitch Surface With A Thin, Long Chain Line, Even In Concealed Portions.

The Program Then Generates The Gear Profile For You.

Related Post: