Metal Deep Drawing

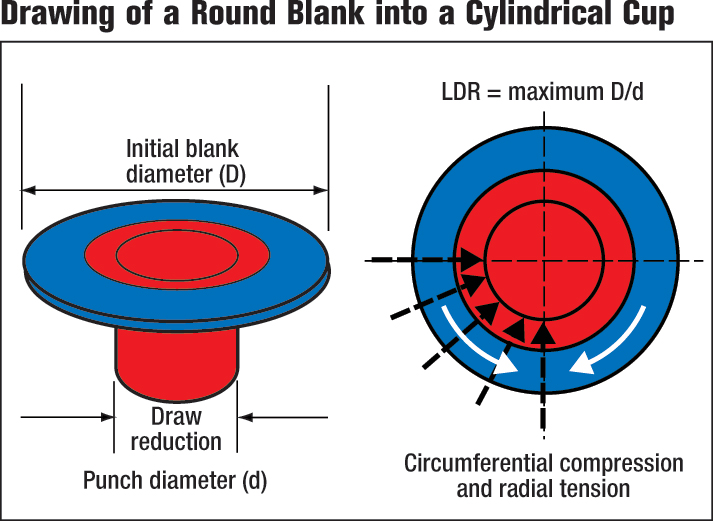

Metal Deep Drawing - [1] it is thus a shape transformation process with material retention. Types of deep drawing parts It is best used for creating components that need a series of diameters. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its. Can deep drawing be used for all metals? The process is considered deep drawing when the depth of the drawn part exceeds its diameter. The deep drawing process is often a combination of stretch. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. Web deep drawing metal working: Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing. Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. When compared to other metal forming methods, deep drawing has. What is deep drawing in sheet metal fabrication? The depth of the drawn parts often exceeds their diameter. The mold for deep drawing is been called deep drawing die. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from. Can deep drawing be used for all metals? Web deep drawing metal working: The mold for deep drawing is been called deep drawing die. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing. Web deep drawing is a processing method that uses a. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The mold for deep drawing is been called deep drawing die. When compared to other metal forming methods, deep drawing. Web deep drawing metal working: Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can. Can deep drawing be used for all metals? [1] it is thus a shape transformation process with material retention. The deep drawing process is often a combination of stretch. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing. Web according to din 8584,. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Can deep drawing be used for all metals? Web deep drawing metal working: Deep drawn parts achieve their shape by. It is best used for creating components that need a series of diameters. Web deep drawing metal working: Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Specifically, if the depth of the item created is. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end. It is best used for creating components that need a series of diameters. What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that. The deep drawing process is often a combination of stretch. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Key elements in deep drawing material type material thickness n and r values blank size and shape part geometry press speed (ram. Can deep drawing be used for all metals? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often exceeds their diameter. It is best used for creating components that need a series of diameters. When compared to other metal forming methods, deep drawing has a wide range of applications. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its. What is deep drawing in sheet metal fabrication? Deep drawing is a sheet metal forming process used industrially to produce. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Types of deep drawing parts Web deep drawing metal working: [1] it is thus a shape transformation process with material retention.

Deep Drawing Of Sheet Metal

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep drawing of sheet metal

Metal deep drawing Tooling/Metal deep drawing Mould YouTube

Deep Draw Metal Stamping Getting Started

DeepDrawing Steel

Metal forming deep drawing of sheet metal

Deep Drawn Methodology and Its Benefits

Deep Drawing of Sheet Metal Stoeckli Metall AG Metalworking Center

Deep Drawing from A to Z MetalForming Magazine Article

Web The Following Are Key Elements Affecting Metal Flow, And Each Of Them Should Be Considered When Designing, Building, Or Troubleshooting Deep Drawing Stamping Dies:

Specifically, If The Depth Of The Item Created Is Equal To Or Greater Than Its Radius, Then The Metal Forming Process Can Be Called Deep Drawing.

Deep Drawn Parts Achieve Their Shape By Drawing Metal Into A Cavity Rather Than By Stretching Or Thinning Over A Die, So The Original Sheet Thickness Remains Essentially The Same From Start To.

The Mold For Deep Drawing Is Been Called Deep Drawing Die.

Related Post: