Rotary Draw Bender

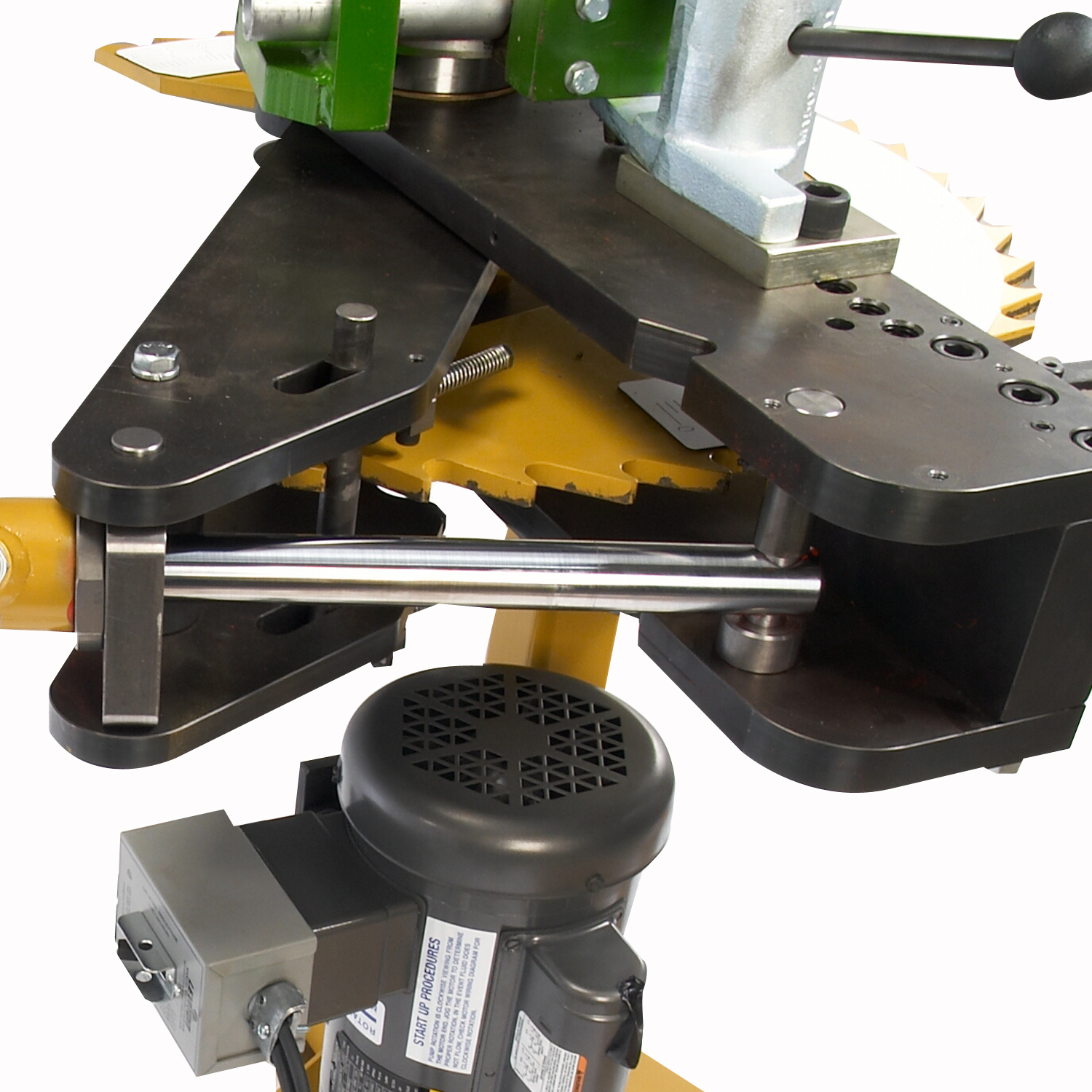

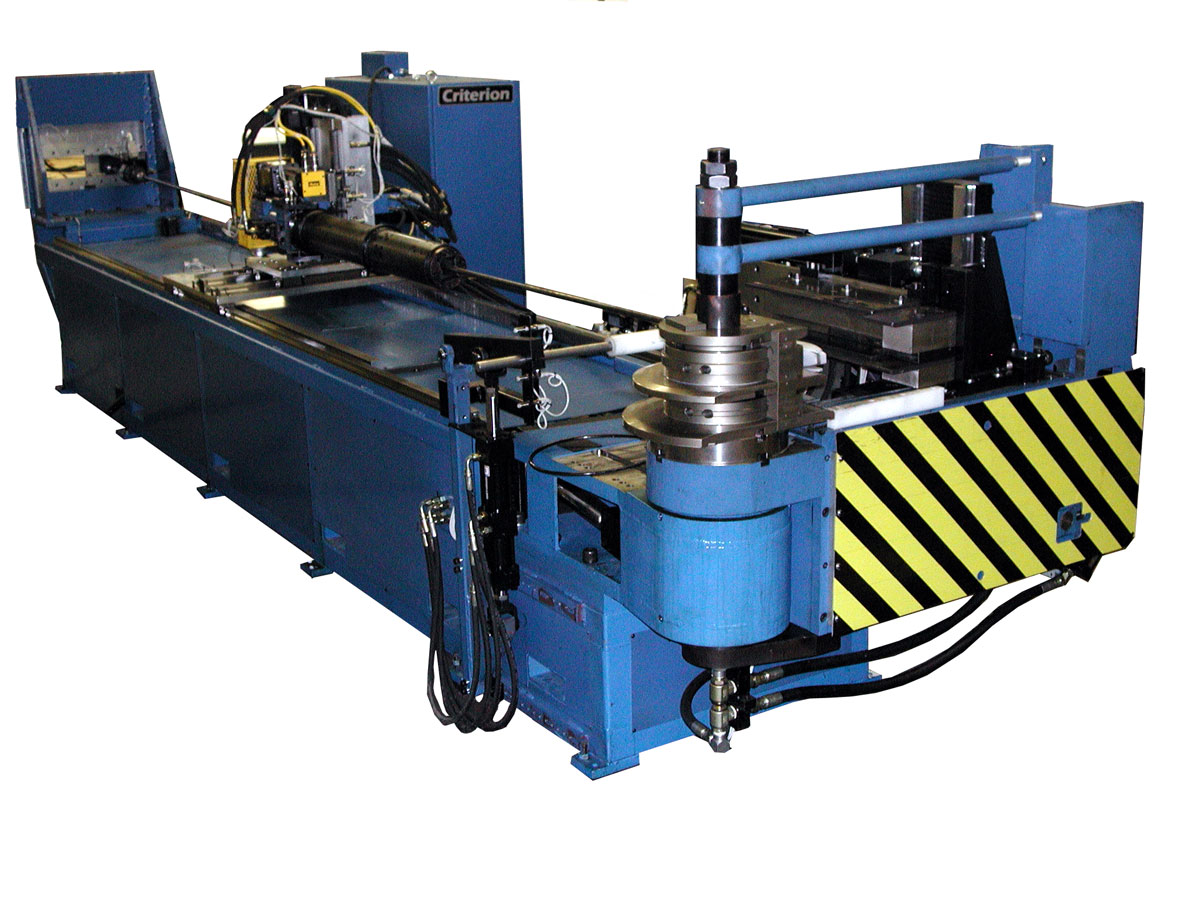

Rotary Draw Bender - The tube is held by the clamp and pressure die, and rotated around the bend die. Simultaneously, the corresponding inner wall of the workpiece becomes thicker and more compressed. Web principles of rotary draw bending bending forces as a tube or pipe is being bent, the outer wall at the point of the bend begins to stretch and thin out. Heavy wall and high tensile materials may reduce rotary draw bending machine capacity. Web search for used rotary draw benders. Web electrical options:110v single phase. Web rotary draw bending uses cnc benders, which can apply enough force to bend denser or thicker material. 2.5 mild steel tube and 2 tube chrome moly capacity. View the video to see ercolina’s super bender sb48 rotary draw bender in action bending 1″ pipe! Ercolina sb48 super bender is ideal for producing consistent quality bends in large diameter pipe, tubes, squares, rectangular, solids and other profiles. 30″ wide by 59″ deep View the video to see ercolina’s super bender sb48 rotary draw bender in action bending 1″ pipe! The final recommendation is ultimately based on actual bend specifications, application/use, and. This type of bending requires a lot more tooling than compression bending. It forms the tube to the specified bend. Normally it takes no longer than 3 minutes. 30″ wide by 59″ deep Web a rotary draw hydraulic bender does allow for either scenario, mandrel or no mandrel. Manual rotary draw tube and pipe bender. Ercolina sb48 super bender is ideal for producing consistent quality bends in large diameter pipe, tubes, squares, rectangular, solids and other profiles. Compare add to wish list. A pressure die, which applies pressure to the outer surface; Web a basic tooling setup on a rotary draw bender includes a bend die, which forms the bends radius; Web electrical options:110v single phase. The tube is held by the clamp and pressure die, and rotated around the bend die. Web one of the most common modes of bending is rotary draw bending. Things to know before purchase: Stores up to 170 programs of 10 bends each in its internal memory and accepts limitless external memory. Web rotary draw bending is the most complex form of bending and requires a toolset to execute. Web rotary draw benders are the most. Find baileigh, ercolina, pines, gmc, edwards, and custom built for sale on machinio. Web a basic tooling setup on a rotary draw bender includes a bend die, which forms the bends radius; Web a rotary draw hydraulic bender does allow for either scenario, mandrel or no mandrel. One, you need a bend die. Heavy wall and high tensile materials may. Web choose from the ercolina catalogue all the rotary draw benders machines, made in italy Web one of the most common modes of bending is rotary draw bending. Manual rotary draw tube and pipe bender. And a collet, which is used to control the flow of material during the bend, transport and rotate the tube. Ercolina sb48 super bender is. The process demands a tight configuration that fits as much tubing as. Web rotary draw benders are the most popular machines for use in bending tube, pipe and solids for applications like: Web search for used rotary draw benders. It is typically used to bend a tube three to four times the centerline radius of the tube diameter. Web discover. Heavy wall and high tensile materials may reduce rotary draw bending machine capacity. Web a rotary draw hydraulic bender does allow for either scenario, mandrel or no mandrel. Rotary draw benders creates perfect bends when the right tooling is matched to the application. Stores up to 170 programs of 10 bends each in its internal memory and accepts limitless external. It forms the tube to the specified bend. Find baileigh, ercolina, pines, gmc, edwards, and custom built for sale on machinio. Compare add to wish list. The final recommendation is ultimately based on actual bend specifications, application/use, and. A clamp die, which clamps the tube to the bend die; Discover the efficiency and precision of rotary draw benders for tube and pipe bending. Web choose from the ercolina catalogue all the rotary draw benders machines, made in italy Manual rotary draw tube and pipe bender. Web rotary draw benders are the most popular machines for use in bending tube, pipe and solids for applications like: Web principles of rotary. Discover the efficiency and precision of rotary draw benders for tube and pipe bending. Web electrical options:110v single phase. All capacities are based on a53 grade a (mild steel) 48,000 psi tensile materials; Heavy wall and high tensile materials may reduce rotary draw bending machine capacity. 30″ wide by 59″ deep Winton machine’s three axis tube benders are designed for precision bending applications in a wide variety of industries such as hvac, aerospace, automotive, and. The process demands a tight configuration that fits as much tubing as. The tube is held by the clamp and pressure die, and rotated around the bend die. And a collet, which is used to control the flow of material during the bend, transport and rotate the tube. A mandrel and wiper support the inside and outside of. This type of bending requires a lot more tooling than compression bending. Web one of the most common modes of bending is rotary draw bending. Web principles of rotary draw bending bending forces as a tube or pipe is being bent, the outer wall at the point of the bend begins to stretch and thin out. There are other benders for square tubing, such as an induction bender, roll bender, heavy duty square tube bender or compression bender, for example. Rotary draw benders creates perfect bends when the right tooling is matched to the application. It is typically used to bend a tube three to four times the centerline radius of the tube diameter.BAILEIGH INDUSTRIAL Progrmble Rotary Draw Bender, 3 In 18F297RDB325

Dimakin RDB127 Rotary Draw Bender Heathrow Engineering and Machinery

RotaryDraw TubeBending Machines, TubeFabricating Systems

New Baileigh Rotary Draw Tube Bender

Industrial Rotary Draw Bender RDB125 EPTEX Coatings

BAILEIGH INDUSTRIAL Hydraulic Rotary Draw Bender, 2.5 In 18F296RDB

New Baileigh Rotary Draw Tube Bender

RotaryDraw TubeBending Machines, TubeFabricating Systems

Baileigh 150AS Rotary Draw Bender

Ercolina Super Bender Rotary Draw Bender, SB48Plus Norman Machine Tool

Web Discover The Power Of Hydraulic Rotary Draw Benders For Precise Tube & Pipe Bending.

*Choose From 3 Bending Speeds, Depending On Material Type, Od, And Wall Thickness, To Proper Speed For Each Application.

Find Baileigh, Ercolina, Pines, Gmc, Edwards, And Custom Built For Sale On Machinio.

Web Rotary Draw Bending Is The Most Complex Form Of Bending And Requires A Toolset To Execute.

Related Post: