Surface Finish Callout On Drawing

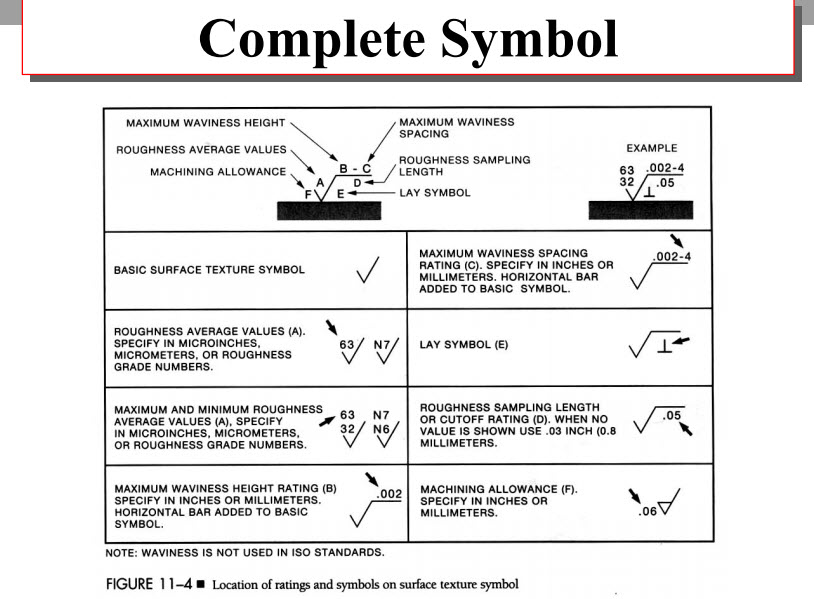

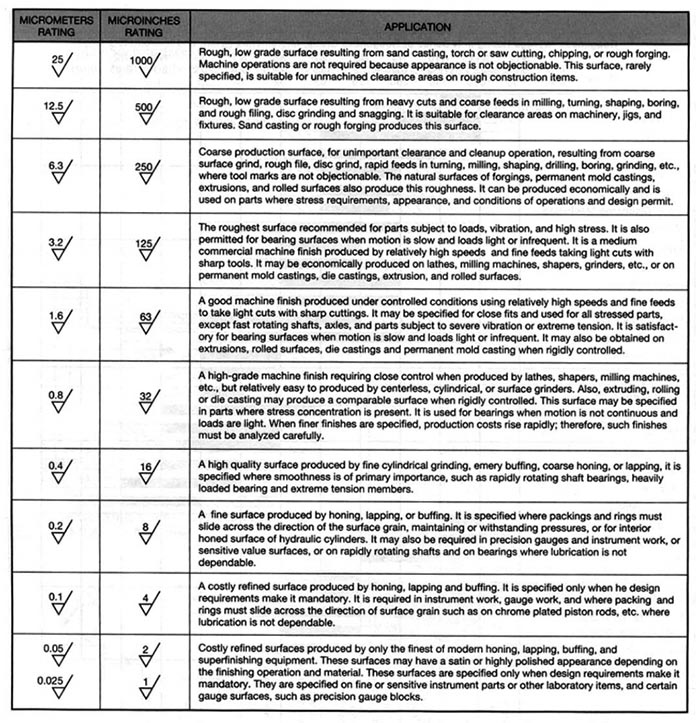

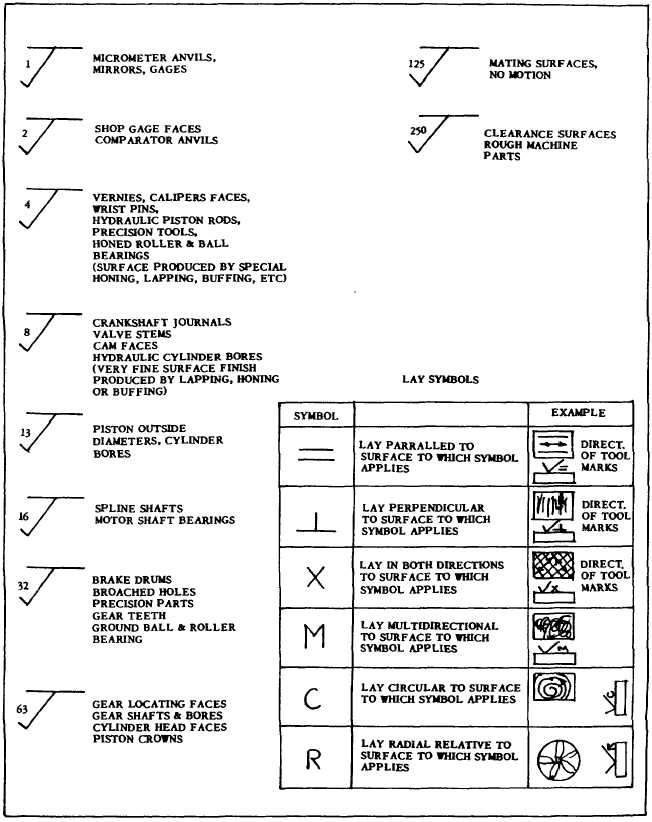

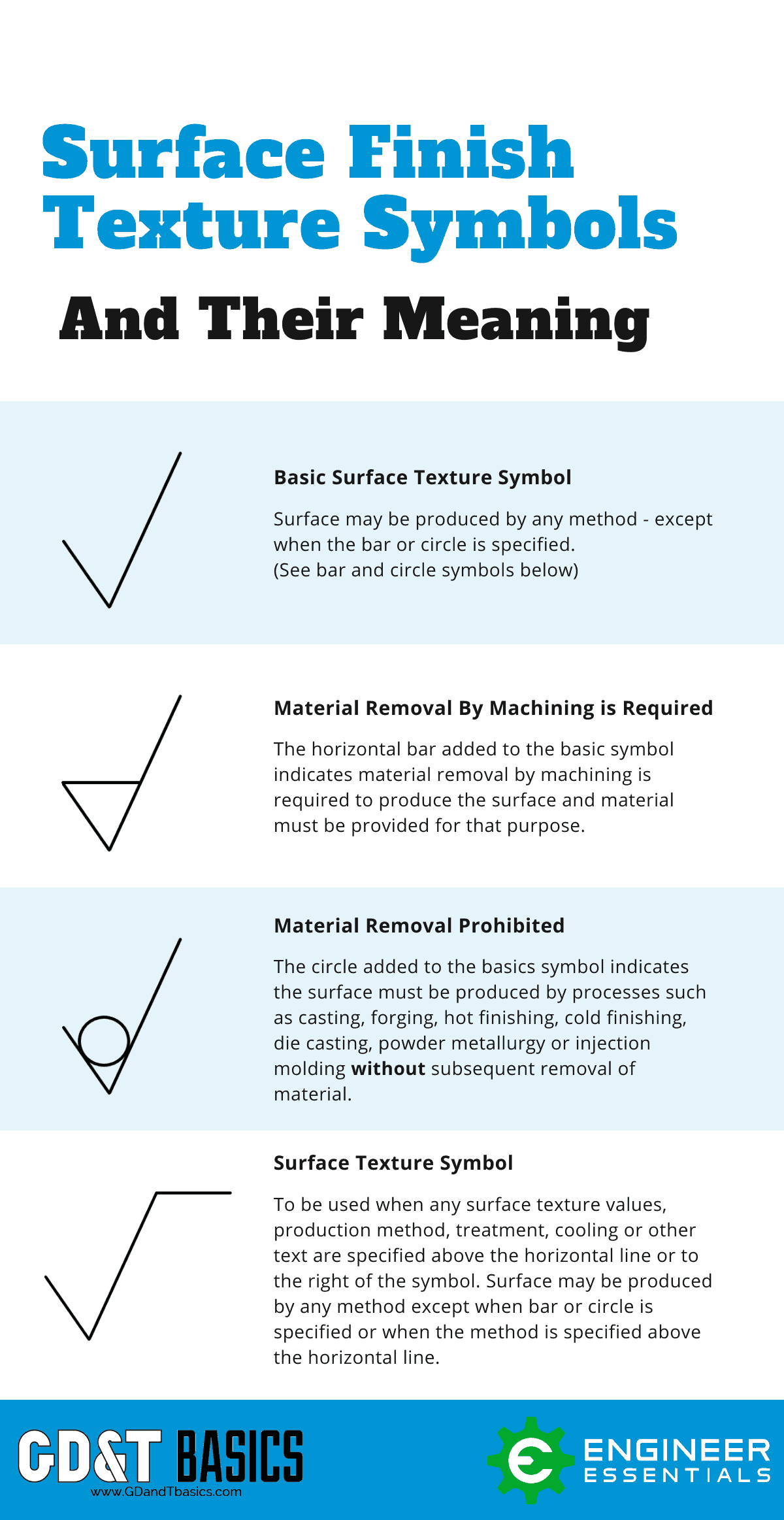

Surface Finish Callout On Drawing - Web surface finish is called out on a drawing to indicate the required level of roughness for a surface. Web surface finish symbols. If it is called out on a curved surface, like a fillet on a welded part, the entire surface where the radius is has to fall within the tolerance zone. The surface finish graphical symbol usage is defined in iso 1302:2002. Web see below for a full list of all surface finish symbols, their meaning, and how they should be applied: The symbols represent various levels of roughness, waviness, and lay, and can be used to analyze the. When you specify a surface finish for a surface that already has one, creo parametric redefines the surface finish information in the part and replaces the old symbol with the new one. Web surface finish symbols for engineering drawings published by gayamadhusanka on may 28, 2023 surface finish symbols are needed to represent the surface texture requirement to manufacturers. There are many variations of the surface texture symbol but most often it is used with a microinch or micrometer value callout that specifies the roughness of a surface. Web definition of surface finish. Finish symbol n finish r a μinch r a μm super finishing: Aside from dimensions and tolerances, another important callout is surface finish. Web surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Their values and general rules for specifying. Web the details in iso surface finish standards relate to surfaces produced. Web see below for a full list of all surface finish symbols, their meaning, and how they should be applied: The bis recommended symbols for indicating the surface finish are shown in table a. Each surface symbol applies to the entire surface. From basics to advanced, symbols to inspection, from cnccookbook, the leading cnc blog on the internet. Web surface. Aside from dimensions and tolerances, another important callout is surface finish. Click surface finish on the annotation toolbar, or click insert > annotations > surface finish symbol. Web surface finish is called out on a drawing to indicate the required level of roughness for a surface. N1 1 0.025 lapping n2 2 0.05 n3 4 0.1 grinding n4 8 0.2. The value included with the symbol tells us the degree of roughness required for the surface. Other iso standards related to surface roughness iso 468:1982 “surface roughness — parameters. Requirements for surface finish are frequently found on technical drawings for mechanical parts, particularly where parts fit together tightly, move against each other, or form a seal. Click in the graphics. So how do you specify surface roughness on a drawing or a specification? They were just simple stepped reducers that were turned down. In this article, we’ll explain the surface roughness symbols, indication, grade numbers, terminology and calculation. Click in the graphics area to place the symbol. Click as many times as necessary to place multiple copies. Web the details in iso surface finish standards relate to surfaces produced by abrading, casting, coating, cutting, etching, plastic deformation, sintering, wear, erosion, and some other methods. Web surface finish symbols. Aside from dimensions and tolerances, another important callout is surface finish. The value included with the symbol tells us the degree of roughness required for the surface. N1 1. Surface roughness or roughness, is a measure of surface irregularities. Set the properties in the propertymanager. For the roughness values greater than 25μm, the symbol is used. The symbols represent various levels of roughness, waviness, and lay, and can be used to analyze the. Web inserting a surface finish symbol. Click in the graphics area to place the symbol. Each surface symbol applies to the entire surface. Surface finish symbols are formed by combining the symbol and lay direction (direction of lay). Passband or sampling length and surface texture parameter symbol and value Requirements for surface finish are frequently found on technical drawings for mechanical parts, particularly where parts fit. Web surface finishes are associated with surfaces in the part, not the entities or views in the drawing. Surface roughness or roughness, is a measure of surface irregularities. Passband or sampling length and surface texture parameter symbol and value The tolerances were fine but surface finish was the worst i ever saw. Web what surface finish or roughness are required. I mean, you could see the tear marks where the tool was plowing the material off. Finish symbol n finish r a μinch r a μm super finishing: The surface roughness is the measure of the total spaced irregularities on the. The value included with the symbol tells us the degree of roughness required for the surface. When you specify. If you are working on cnc machining parts or some other manufacturing process. The bis recommended symbols for indicating the surface finish are shown in table a. Web surface finish is the term used to describe the texture of a surface, and it is sometimes used interchangeably with the term surface texture. There are many variations of the surface texture symbol but most often it is used with a microinch or micrometer value callout that specifies the roughness of a surface. The symbols represent various levels of roughness, waviness, and lay, and can be used to analyze the. When you specify a surface finish for a surface that already has one, creo parametric redefines the surface finish information in the part and replaces the old symbol with the new one. Web you can specify the surface texture of a part face by using a surface finish symbol. Web a symbol for defining the surface finish of a part. Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designer’s intent. Complete guide to surface finish symbols, roughness charts, ra, rz, measurements, and callouts. Surface finish symbols are formed by combining the symbol and lay direction (direction of lay). Web definition of surface finish. The tolerances were fine but surface finish was the worst i ever saw. Requirements for surface finish are frequently found on technical drawings for mechanical parts, particularly where parts fit together tightly, move against each other, or form a seal. For the roughness values greater than 25μm, the symbol is used. Web surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.

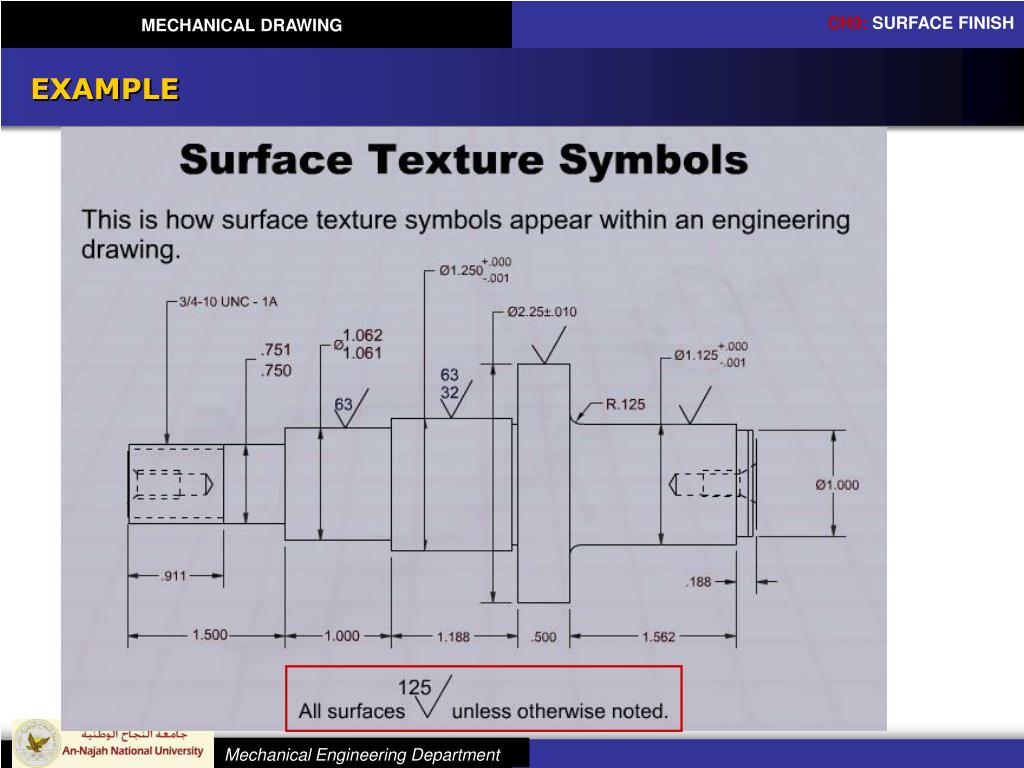

Surface Finish Call Out On Drawings

Surface Finish Lay Symbols

surface finish symbols in engineering drawing

need help identifying a surface finish call out

Surface finish

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Engineering drawing question how to specify a surface must be smooth

The Basics of Surface Finish GD&T Basics

Surface Finish Symbols Get It Made

PPT MECHANICAL DRAWING Chapter 9 SURFACE FINISH PowerPoint

Web It Is Suggested To Indicate The Surface Roughness On Drawing By Symbols.

The Value Included With The Symbol Tells Us The Degree Of Roughness Required For The Surface.

Web What Surface Finish Or Roughness Are Required And How To Indicate Roughness In Drawing?

Click Surface Finish On The Annotation Toolbar, Or Click Insert > Annotations > Surface Finish Symbol.

Related Post: