Wire Drawing Process

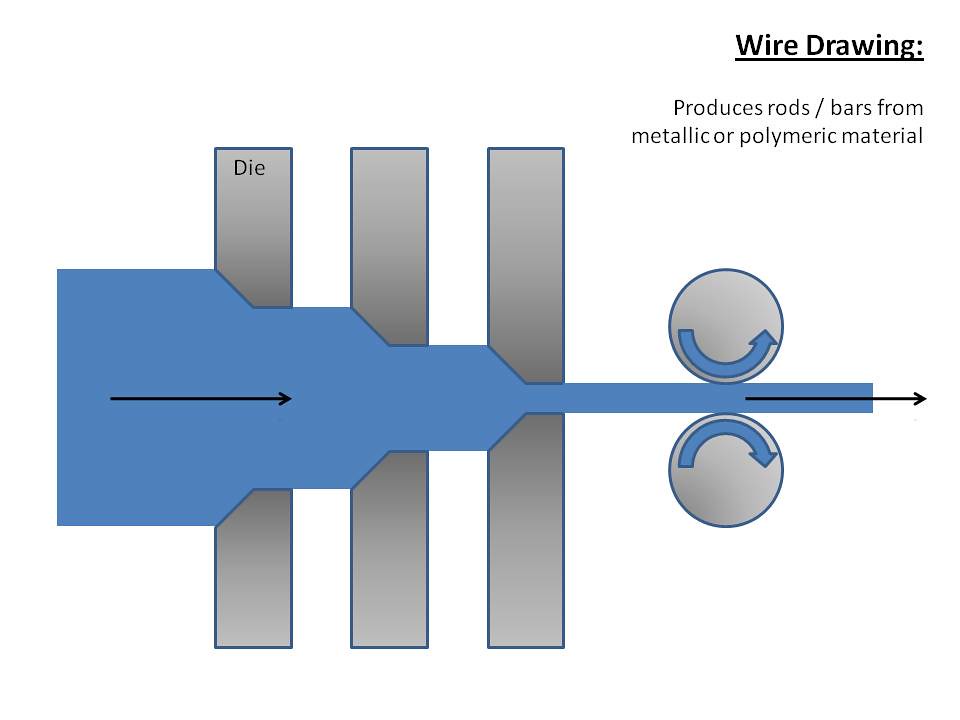

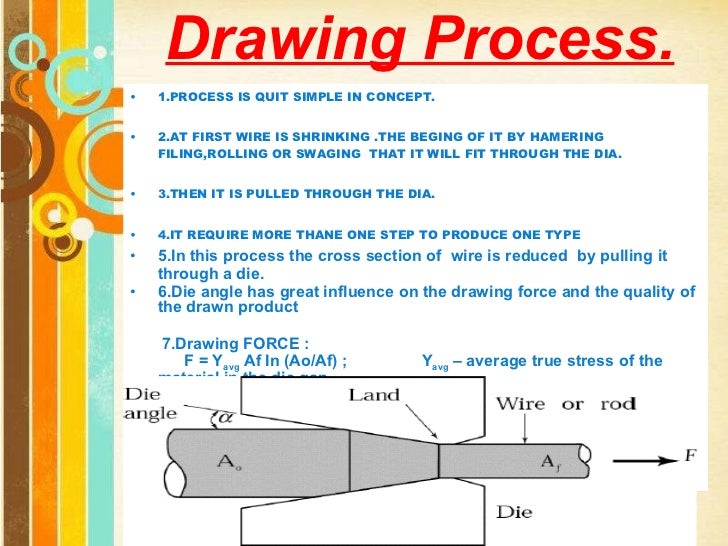

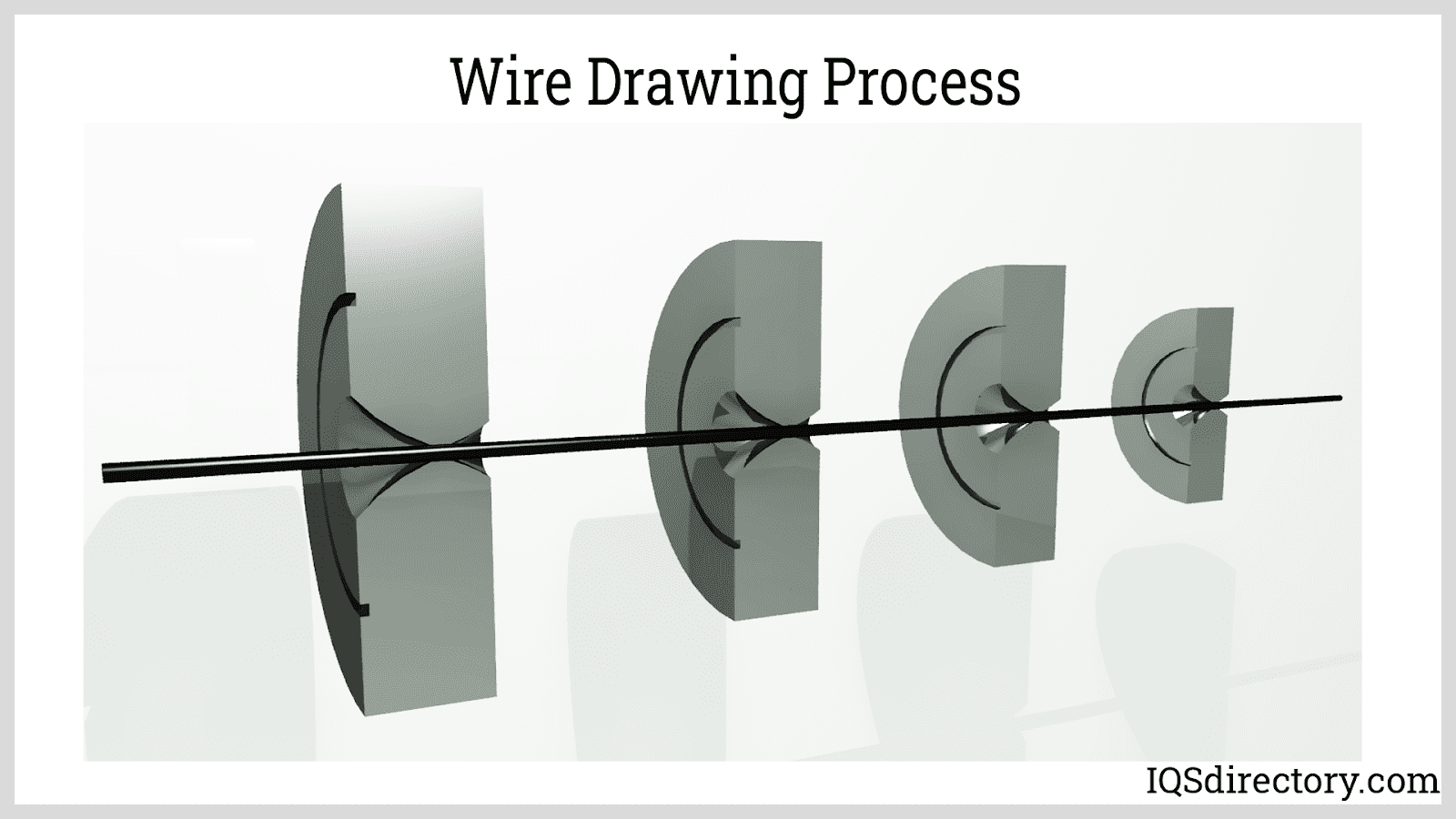

Wire Drawing Process - Web wire drawing consists of pulling a metal wire through a small circular opening called a die. Download a pdf of wire drawing process. Diamonds dies are used for small diameter wire. Web wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. The process is clearly explained in detail. A wire is a circular, small diameter flexible rod. Wire drawing is an cold working process. Web stages of wire drawing process 1. Web stainless steel wire drawing is a metalworking process that involves pulling a metal wire through a series of dies to reduce its diameter and increase its length. Introduction drawing operations involve pulling metal through a die by means of a tensile force applied to the exit side of the die. Drawing metal wire through a drawplate offers you the flexibility of a variety of diameters of wire without having to carry a large stock. Web wire drawing consists of pulling a metal wire through a small circular opening called a die. As the material is pulled through the cone, it undergoes plastic deformation and gradually undergoes a. Web stainless steel. Web wire drawing is a metal processing process. Tube drawing is also similar. Forging is the plastic, or permanent, changing of a metal shape. Web wire drawing process. Download a pdf of wire drawing process. Wire drawing is a cold plastic deformation process by which the diameter of a rod or a wire is reduced and its length is increased by pulling the workpiece through a calibrated hole of a conical die. Before you can start the wire drawing process, you need to prepare the wire. Web stages of wire drawing process 1. This involves. Diamonds dies are used for small diameter wire. Forging is the plastic, or permanent, changing of a metal shape. The process is clearly explained in detail. Web this lecture describes the fundamentals of wire drawing including working principle, mechanism, calculation of various parameters, advantages, disadvantages and applications. Tube drawing is also similar. Web wire drawing process. The included angle of the cone is kept between 8 to 24°. Tube drawing is also similar. The wire's end must be pointed so that it can be easily inserted into the die. Forging is the plastic, or permanent, changing of a metal shape. The process is clearly explained in detail. Rod drawing is similar process like wire drawing except it is rigid and has larger diameter compare to. This involves cleaning the wire to remove. Web wire drawing is a metal processing process. Wire drawing is an cold working process. Tube drawing is also similar. The process is clearly explained in detail. Wire drawing is a cold plastic deformation process by which the diameter of a rod or a wire is reduced and its length is increased by pulling the workpiece through a calibrated hole of a conical die. The process increases the tensile and yield. Web stainless steel wire. Rod drawing is similar process like wire drawing except it is rigid and has larger diameter compare to. Forging can be performed at hot, warm or cold temperatures. One meter of 5.5 mm wire rod can be drawn to 30 meters with 1 mm diameter, or 484 meters with 0.25 mm diameter. Web wire drawing is a metal processing process.. The process is clearly explained in detail. Web wire drawing consists of pulling a metal wire through a small circular opening called a die. Tube drawing is also similar. Pull too hard and the metal will break. The pulling force is limited by the strength of the material: Rod drawing is similar process like wire drawing except it is rigid and has larger diameter compare to. The pulling force is limited by the strength of the material: Web wire drawing, making of wire, generally from a rod or bar. The finished wire is coiled onto a motor driven block. Introduction drawing operations involve pulling metal through a die. Pull too hard and the metal will break. This involves cleaning the wire to remove. The dies are manufactured from hard material e.g tungsten carbide. Wire drawing is a simple process. Web wire drawing process. Similarly rods are drawn from steel rounds of larger diameters. Forging is the plastic, or permanent, changing of a metal shape. This process is a type of forging. The subsequent drawing die must have smaller bore diameter than the previous drawing die. The process can be used to create wires of different sizes and shapes, depending on. The wire's end must be pointed so that it can be easily inserted into the die. Web this lecture describes the fundamentals of wire drawing including working principle, mechanism, calculation of various parameters, advantages, disadvantages and applications. Web stainless steel wire drawing is a metalworking process that involves pulling a metal wire through a series of dies to reduce its diameter and increase its length. In this figure, a 0 is the initial sectional area, a f the final one, f the drawing force, and α the drawing angle. The finished wire is coiled onto a motor driven block. Forging can be performed at hot, warm or cold temperatures.

Wire drawing This resource is a diagram of the wire drawin… Flickr

Wire drawing ppt

wire drawing setup

What is wire drawing process? Wire Drawing Machines Mashtronics

What is wire drawing process? Wire Drawing Machines Mashtronics

Wire Cloth What Is It? How Is It Used? Materials, Types

10 Wire Drawing Process Download Scientific Diagram

Wire Drawing Process(Parts And Working) YouTube

Wire Drawing Process YouTube

![1 Wire drawing process [1] Download Scientific Diagram](https://www.researchgate.net/profile/Aditya-Narayan/publication/341164285/figure/fig4/AS:887903240605696@1588704037081/3D-Wire-drawing-process_Q640.jpg)

1 Wire drawing process [1] Download Scientific Diagram

The Included Angle Of The Cone Is Kept Between 8 To 24°.

Web Figure 1 Shows The Basics Of The Drawing Process.

Wire Drawing Is A Cold Plastic Deformation Process By Which The Diameter Of A Rod Or A Wire Is Reduced And Its Length Is Increased By Pulling The Workpiece Through A Calibrated Hole Of A Conical Die.

Introduction Drawing Operations Involve Pulling Metal Through A Die By Means Of A Tensile Force Applied To The Exit Side Of The Die.

Related Post: